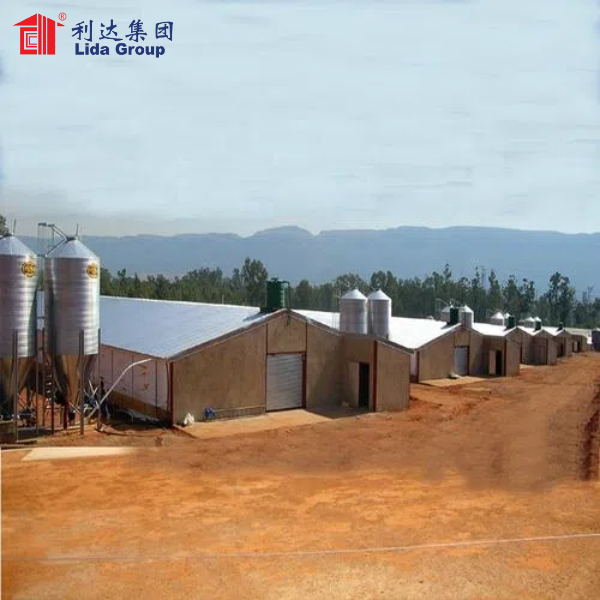

In the ever-evolving world of agriculture, poultry farming stands out as a significant contributor to food production. As the demand for poultry products rises, so does the need for efficient, durable, and adaptable farming structures. Lida Group, a leader in the design and construction of steel structures, offers customized solutions that can transform poultry farmhouses into highly functional, cost-effective, and sustainable environments. This article explores the benefits of using Lida Group’s steel structures in poultry farming, the design possibilities, and how these innovations can enhance productivity and sustainability in the industry.

Understanding the Importance of Poultry Farm Structures

The Role of Poultry Farmhouses

Poultry farmhouses play a crucial role in the health and productivity of birds. Proper housing protects poultry from harsh weather conditions, predators, and disease while providing suitable environments for growth and egg production. The design of these structures significantly impacts operational efficiency, animal welfare, and ultimately, profitability.

Challenges in Traditional Poultry Farming Structures

Traditional poultry housing often faces several challenges:

- Durability: Many conventional structures are susceptible to environmental wear and may require frequent repairs or replacements.

- Ventilation: Poor ventilation can lead to heat stress, respiratory issues, and reduced productivity among birds.

- Space Utilization: Inefficient use of space can hinder the growth of poultry and limit the number of birds that can be raised.

- Biosecurity: Ensuring a disease-free environment is critical in poultry farming, and traditional structures may not fully support biosecurity measures.

The Advantages of Steel Structures for Poultry Farming

Lida Group specializes in customized steel structures that address the challenges faced by traditional poultry farmhouses. Here are some of the key benefits:

1. Durability and Longevity

Steel structures are renowned for their durability. Unlike wood or other materials, steel is resistant to pests, rot, and extreme weather conditions. Lida Group’s steel constructions are designed to withstand the rigors of poultry farming, providing a long-lasting solution that minimizes maintenance costs and extends the lifespan of the building.

2. Customization Options

Every poultry farm has unique requirements, and Lida Group understands this. Their steel structures can be tailored to meet specific needs, whether it’s adjusting the size, layout, or features of the building. This level of customization allows farmers to optimize their operational efficiency and create an environment that best supports their poultry.

3. Improved Ventilation and Climate Control

Effective ventilation is essential for maintaining a healthy environment for poultry. Lida Group’s designs incorporate advanced ventilation systems that promote airflow and regulate temperature. This leads to improved bird health, enhanced growth rates, and better production outcomes.

4. Biosecurity Measures

Lida Group’s steel structures can be designed to enhance biosecurity protocols. Features such as controlled entry points, sanitizing stations, and easy-to-clean surfaces help prevent the introduction and spread of diseases. This is particularly important in maintaining the health of the flock and ensuring high-quality production.

5. Cost-Effectiveness

While the initial investment in steel structures may be higher than traditional materials, the long-term savings are significant. Reduced maintenance costs, energy efficiency, and increased productivity lead to a favorable return on investment. Lida Group’s steel structures are designed to maximize efficiency, ultimately benefiting the bottom line for poultry farmers.

Design Possibilities with Lida Group’s Steel Structures

1. Flexible Layouts

Lida Group offers a variety of design options that can be adapted to the specific needs of poultry farmers. Whether it’s a free-range system, cage-free environment, or a more conventional layout, the flexibility in design allows farmers to optimize their operations. This adaptability is crucial in accommodating different farming practices and future growth.

2. Space Optimization

Effective space utilization is critical in poultry farming. Lida Group’s steel structures can be designed with multi-level capabilities, enabling farmers to maximize vertical space. This is particularly beneficial in areas with limited land availability, allowing for a larger number of birds without needing to expand the footprint of the farm.

3. Integrated Technology

Modern poultry farming increasingly relies on technology for monitoring and management. Lida Group’s structures can be equipped with smart technology, including temperature and humidity sensors, automated feeding systems, and monitoring cameras. This integration enhances operational efficiency and allows farmers to make informed decisions based on real-time data.

4. Sustainable Features

Sustainability is becoming a priority in agriculture. Lida Group’s steel structures can incorporate eco-friendly features such as solar panels, rainwater harvesting systems, and energy-efficient insulation. These elements not only reduce the environmental impact but also lower operational costs, making the farm more sustainable in the long run.

Implementation of Lida Group’s Steel Structures

1. Planning and Consultation

The process begins with a comprehensive consultation to understand the specific needs and goals of the poultry farm. Lida Group’s team of experts collaborates with farmers to develop a tailored plan that considers factors such as bird type, production goals, and farm layout.

2. Design Development

Once the initial planning is complete, Lida Group’s architects and engineers work on the design of the steel structure. This phase involves creating detailed blueprints that incorporate the desired features, ensuring that the structure meets all regulatory requirements and industry standards.

3. Manufacturing

After finalizing the design, the components of the steel structure are manufactured in Lida Group’s state-of-the-art facilities. Utilizing advanced technology and high-quality materials, each component is fabricated to ensure precision and durability.

4. Construction and Assembly

Following manufacturing, the components are transported to the farm site for assembly. Lida Group’s experienced construction team ensures that the structure is erected efficiently and safely. The assembly process is streamlined, reducing construction time and minimizing disruption to existing farm operations.

5. Final Inspection and Handover

Once the construction is complete, a thorough inspection is conducted to ensure that the structure meets all specifications and quality standards. After passing inspection, the new poultry farmhouse is handed over to the farmer, ready for operation.

Case Studies: Successful Transformations

Case Study 1: A Large-Scale Poultry Farm

Lida Group partnered with a large-scale poultry farm struggling with outdated wooden structures. The farm faced issues with maintenance costs and biosecurity challenges. By replacing the existing buildings with customized steel structures, the farm improved its operational efficiency and reduced costs. The new design included advanced ventilation systems and enhanced biosecurity features, leading to healthier birds and increased production.

Case Study 2: A Family-Owned Poultry Business

A family-owned poultry business sought to modernize its facilities to accommodate a growing demand for organic eggs. Lida Group designed a series of steel structures that provided a free-range environment while maximizing space. The integration of sustainable features, such as solar panels and rainwater collection, significantly reduced the farm’s environmental impact and operational costs, allowing the family to focus on quality and sustainability.

The Future of Poultry Farming with Steel Structures

1. Innovations in Design and Technology

As technology continues to advance, the design and functionality of poultry farmhouses are expected to evolve. Lida Group is committed to integrating the latest innovations in construction and agricultural technology, ensuring that farmers have access to the best solutions available.

2. Emphasis on Sustainability

The push for sustainable agricultural practices will continue to grow. Lida Group’s steel structures can be at the forefront of this movement, offering environmentally friendly solutions that benefit both farmers and the planet. By prioritizing sustainability, poultry farms can contribute to global efforts to reduce carbon footprints and promote responsible farming practices.

3. Increased Demand for Customization

As the poultry industry diversifies, the demand for customized solutions will rise. Lida Group is well-positioned to meet this demand with its flexible design options and commitment to understanding the unique needs of each farm. This adaptability will empower farmers to create structures tailored to their specific goals, whether they focus on production, sustainability, or animal welfare.

4. Global Expansion of Steel Structures

The success of Lida Group’s steel structures in poultry farming is likely to inspire similar initiatives worldwide. As more farmers recognize the benefits of steel construction, the global market for customized poultry farmhouses will expand. Lida Group’s expertise and innovative designs will play a pivotal role in shaping the future of poultry farming on a global scale.

Conclusion

Lida Group’s customized steel structures offer a transformative solution for poultry farmers seeking to enhance their operations. With numerous benefits, including durability, customization, and improved biosecurity, steel structures represent a significant advancement over traditional poultry housing.

By partnering with Lida Group, farmers can create efficient, sustainable, and productive environments that support the health and growth of their poultry. As the poultry industry continues to evolve, the adoption of innovative solutions like Lida Group’s steel structures will be crucial in meeting the demands of a changing market.

Investing in a customized steel structure is not just a decision for today; it is a strategic choice for a sustainable and successful future in poultry farming. With Lida Group’s expertise, farmers can build the foundation for a thriving poultry business that prioritizes efficiency, quality, and animal welfare.

Contact Us

Post time: Jan-24-2025