As the global demand for poultry products continues to rise, the need for cost-effective, efficient, and sustainable farming solutions has never been more critical. Poultry farming, in particular, requires specialized buildings that can accommodate the unique needs of birds while ensuring biosecurity and operational efficiency. Lida Group, a leader in steel structure construction, offers innovative low-cost steel structure poultry farming buildings that meet these requirements. This guide explores the benefits, design considerations, construction process, and best practices for implementing low-cost steel structure poultry farms.

Understanding the Need for Low-Cost Poultry Farming Buildings

The Challenges Facing Poultry Farmers

Poultry farmers today face several challenges, including:

- Rising Production Costs: The increasing costs of feed, labor, and utilities make it essential for farmers to find ways to reduce overhead expenses.

- Biosecurity Risks: Protecting poultry from diseases is a top priority, necessitating facilities that are easy to clean and secure.

- Environmental Control: Poultry require specific temperature and humidity conditions to thrive, which means buildings must be designed for effective climate control.

- Space Limitations: As urbanization increases, finding adequate land for poultry farming can be challenging, making efficient use of space vital.

The Role of Steel Structures

Steel structures offer a practical solution to these challenges. They combine strength, durability, and flexibility, making them ideal for poultry farming. Moreover, steel buildings can be constructed quickly and at a lower cost compared to traditional materials, allowing farmers to invest more in their operations.

Benefits of Low-Cost Steel Structure Poultry Farming Buildings

1. Cost-Effectiveness

One of the primary advantages of steel structure poultry buildings is their cost-effectiveness. Key factors contributing to lower costs include:

- Material Savings: Steel is often more affordable than traditional construction materials like wood or concrete, particularly when considering long-term durability.

- Reduced Labor Costs: The prefabrication of steel components allows for quicker assembly on-site, reducing labor costs associated with construction.

- Lower Maintenance Expenses: Steel structures are resistant to rot, pests, and weathering, resulting in lower maintenance costs over their lifespan.

2. Durability and Strength

Steel structures are designed to withstand harsh environmental conditions, including extreme weather. This durability ensures that poultry are protected from external threats, helping to maintain healthy flocks and maximize production.

3. Customization Options

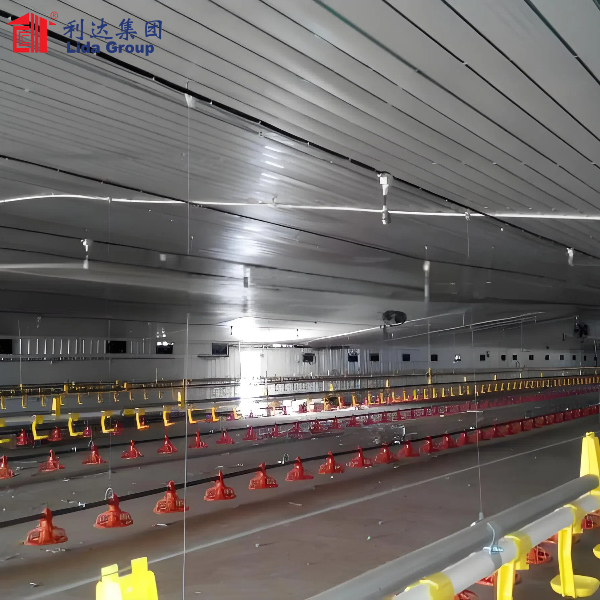

Lida Group specializes in providing customized solutions that cater to the specific needs of poultry farmers. Whether it’s designing a building for broilers, layers, or free-range birds, Lida Group can tailor the design to meet operational requirements. Custom features may include:

- Ventilation Systems: Effective airflow is crucial for poultry health, and steel buildings can incorporate advanced ventilation solutions.

- Biosecurity Measures: Controlled access points and smooth surfaces in steel structures enhance biosecurity, reducing the risk of disease transmission.

4. Speed of Construction

The prefabrication of steel components allows for rapid construction. This speed is particularly beneficial for farmers looking to establish new facilities or expand existing ones without significant downtime. Lida Group’s efficient building processes ensure minimal disruption to ongoing operations.

5. Eco-Friendliness

Steel is a recyclable material, and many components used in steel structures come from recycled sources. This focus on sustainability aligns with the growing consumer demand for environmentally friendly farming practices, making steel structures an attractive option for forward-thinking poultry farmers.

Design Considerations for Steel Structure Poultry Buildings

1. Space Planning

Effective space planning is essential for maximizing efficiency in poultry farming. Key considerations include:

- Bird Density: Determine the optimal space per bird to ensure their welfare and productivity. This is influenced by the type of poultry, their growth stage, and housing conditions.

- Workflow Efficiency: Design the layout to facilitate efficient movement of birds, feed, and equipment, minimizing labor and time.

2. Ventilation and Environmental Control

Proper ventilation is critical for maintaining a healthy environment for poultry. Design features to consider include:

- Natural Ventilation: Incorporate windows and vents to promote airflow and reduce reliance on mechanical systems.

- Mechanical Systems: In areas with extreme climates, integrate HVAC systems that can regulate temperature and humidity effectively.

3. Biosecurity Features

To safeguard poultry health, biosecurity measures should be integrated into the design. Consider the following:

- Controlled Access: Design entry points that limit access to essential personnel only, reducing the risk of disease introduction.

- Sanitation Stations: Include designated areas for washing and disinfecting equipment and footwear before entering the poultry house.

4. Utility and Storage Areas

Efficient utility management is essential for poultry farming. Design considerations should include:

- Feed Storage: Incorporate adequate storage for feed to prevent spoilage and contamination.

- Waste Management: Plan for efficient waste management systems that facilitate easy cleaning and maintenance.

The Construction Process of Steel Structure Poultry Buildings

1. Initial Consultation and Design

The process begins with an initial consultation between Lida Group and the client. This step is crucial for understanding the specific needs of the poultry farm, including:

- Operational Requirements: Discuss the type of poultry, production goals, and any unique challenges.

- Budget and Timeline: Establish a clear budget and timeline for the project to ensure that expectations are aligned.

2. Customized Design Development

Once the requirements are established, Lida Group’s design team creates tailored blueprints that incorporate the desired features and layout. Clients can expect to receive detailed plans showcasing how the building will meet their operational needs.

3. Prefabrication of Steel Components

After finalizing the design, steel components are prefabricated in a controlled environment. This step ensures each piece is manufactured to precise specifications, enhancing quality and reducing waste.

4. On-Site Assembly

Once the prefabricated components are ready, they are transported to the construction site for assembly. Lida Group’s skilled construction team ensures the building is erected safely and efficiently, minimizing disruptions to the client’s operations.

5. Final Inspection and Handover

Upon completion of construction, a thorough inspection is conducted to ensure that all aspects of the building meet quality and safety standards. Once approved, the building is handed over to the client, allowing them to begin utilizing the facility immediately.

Best Practices for Operating Steel Structure Poultry Farms

1. Regular Maintenance

While steel structures require less maintenance than traditional buildings, regular inspections and maintenance are essential to ensure longevity. Key practices include:

- Routine Inspections: Conduct regular checks for signs of wear and tear, particularly in ventilation systems and biosecurity measures.

- Cleaning Protocols: Implement daily and seasonal cleaning routines to maintain hygiene and reduce disease risks.

2. Monitoring Environmental Conditions

Utilize technology to monitor temperature, humidity, and air quality within the poultry buildings. Automated systems can help ensure that conditions remain optimal, promoting bird health and productivity.

3. Employee Training

Ensure that all staff are trained in biosecurity protocols, animal welfare practices, and emergency procedures. This training is crucial for maintaining a safe and productive environment.

4. Waste Management

Implement effective waste management practices to minimize environmental impact and maintain hygiene. Regularly schedule waste removal and ensure that disposal methods comply with local regulations.

5. Sustainable Practices

Adopt sustainable farming practices, such as:

- Water Conservation: Implement water-saving technologies and practices to reduce consumption.

- Renewable Energy Integration: Explore options for integrating renewable energy sources, such as solar panels, to reduce energy costs and environmental impact.

Case Studies: Successful Low-Cost Steel Structure Poultry Buildings by Lida Group

1. Broiler Farm Expansion

A large broiler farm sought to expand its operations to meet increasing demand. Lida Group designed a low-cost steel structure that included multiple climate-controlled sections for different growth stages. The facility was completed on time and within budget, resulting in increased production capacity without compromising biosecurity.

2. Layer Housing Facility

An egg producer approached Lida Group to design a new layer housing facility that prioritized bird welfare and operational efficiency. The resulting steel structure featured advanced ventilation systems and automated egg collection. The client reported improved egg quality and reduced labor costs following the implementation of the new facility.

3. Free-Range Poultry Shelter

A small-scale organic poultry farmer needed a cost-effective solution for free-range birds. Lida Group provided a steel structure that allowed for ample outdoor access while ensuring protection from predators. The design facilitated easy cleaning and maintenance, contributing to healthier birds and higher production rates.

The Future of Poultry Farming with Steel Structures

1. Technological Advancements

The integration of technology in poultry farming is on the rise. Innovations such as IoT devices for monitoring environmental conditions and automated feeding systems are becoming standard in modern poultry facilities. Lida Group’s steel structures can easily accommodate these technologies, creating smart farming environments that enhance efficiency and productivity.

2. Resilience Against Climate Change

As climate change continues to impact agricultural practices, poultry farmers must adapt to changing conditions. Steel structures offer resilience against extreme weather events, ensuring that facilities remain operational regardless of external conditions. This durability is crucial for maintaining consistent production levels in the face of climate challenges.

3. Sustainability and Consumer Demand

As consumers become more environmentally conscious, the demand for sustainably produced poultry is increasing. Steel structures, with their recyclability and energy-efficient designs, align with this demand. Lida Group’s commitment to sustainability positions its low-cost steel solutions as a preferred choice for forward-thinking poultry farmers.

4. Global Expansion of Poultry Markets

The global poultry market is expected to continue expanding, presenting opportunities for farmers to increase production. Lida Group’s steel structure solutions provide the scalability and flexibility needed to meet this growing demand. As farmers look to expand their operations, Lida Group’s innovative designs will play a crucial role in shaping the future of poultry farming.

Conclusion

Low-cost steel structure poultry farming buildings by Lida Group offer a practical and efficient solution for modern poultry farmers facing rising production costs and operational challenges. With their durability, customization options, and eco-friendly design, steel structures provide an attractive alternative to traditional building methods.

As the poultry industry continues to evolve, Lida Group’s commitment to innovation, sustainability, and customer satisfaction ensures that it remains at the forefront of this transformation. By investing in low-cost steel structures, poultry farmers can enhance their operational efficiency, improve animal welfare, and contribute to a more sustainable future.

In a world where the demand for poultry is rising, Lida Group stands ready to help farmers build the facilities of tomorrow, ensuring they are equipped to meet the challenges of today and beyond. Embracing low-cost steel structure solutions is not just a choice for efficiency; it is a step toward a more sustainable and prosperous future in poultry farming.

Contact Us

Post time: Jan-16-2025