In the ever-evolving landscape of construction and industrial design, steel structure buildings and workshops have emerged as the preferred choice for many industries. Their durability, flexibility, and cost-effectiveness make them ideal for a diverse range of applications, from manufacturing facilities to warehouses and agricultural buildings. Lida Group stands out as a leader in this sector, offering customized steel structure solutions that cater to the specific needs of clients across various industries. This article explores the advantages of steel structures, the customization options available, and how Lida Group is reshaping the future of construction.

Understanding Steel Structure Buildings

What Are Steel Structure Buildings?

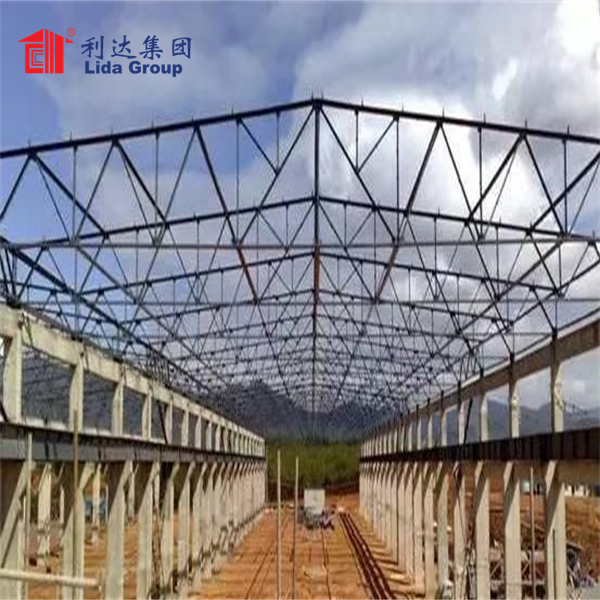

Steel structure buildings are constructed primarily using steel frames, which provide strength and stability. These buildings can be designed for various purposes, including commercial, industrial, agricultural, and residential applications. The use of steel as the primary material allows for large open spaces, minimal internal supports, and flexible designs.

Why Choose Steel Structures?

The choice of steel structures over traditional building methods comes with numerous advantages:

- Durability and Longevity: Steel is inherently resistant to harsh weather conditions, pests, and decay. This durability ensures that steel structures have a longer lifespan than conventional buildings.

- Cost-Effectiveness: Steel structures often require less material and labor for construction, leading to lower overall costs. Additionally, their long lifespan and minimal maintenance needs contribute to long-term savings.

- Flexibility and Design Options: Steel can be easily molded and fabricated into various shapes and sizes, allowing for customized designs that meet specific requirements. This flexibility is particularly beneficial for businesses that need to adapt their operations over time.

- Quick Construction: Prefabricated steel components can be manufactured off-site and assembled quickly on-site, reducing construction time and minimizing disruptions to ongoing operations.

- Sustainability: Steel is recyclable, making it an environmentally friendly choice. The use of steel structures can contribute to LEED certification and other sustainability goals.

Lida Group’s Commitment to Customization

1. Tailored Design Solutions

Lida Group understands that every client has unique needs and specifications. Their approach to customization begins with a comprehensive consultation process:

- Needs Assessment: Lida Group’s team works closely with clients to understand their specific requirements, including the intended use of the building, size, layout, and any special features needed.

- Customized Designs: Based on the assessment, Lida Group offers tailored design solutions that align with the client’s vision. Whether it’s a manufacturing plant, workshop, or storage facility, the designs are optimized for functionality and efficiency.

2. Diverse Applications

Lida Group specializes in customizing steel structures for a wide range of applications:

- Industrial Buildings: From factories to processing plants, Lida Group designs steel structures that meet the demands of various industrial operations.

- Workshops and Garages: Customized workshops can be designed to accommodate specific tools and equipment, providing an efficient and organized work environment.

- Commercial Spaces: Retail and office spaces can also benefit from steel structure designs, offering modern aesthetics and practicality.

- Agricultural Buildings: Lida Group provides solutions for barns, livestock shelters, and storage facilities, ensuring durability and functionality in agricultural settings.

3. Advanced Technology and Engineering

Lida Group leverages advanced technology and engineering practices in the design and construction of steel structures:

- 3D Modeling and Visualization: Utilizing sophisticated software, Lida Group creates detailed 3D models of proposed structures, allowing clients to visualize the final product and make informed decisions.

- Structural Analysis: Comprehensive structural analysis ensures that all designs meet safety and performance standards, providing clients with peace of mind.

- Innovative Materials: Lida Group uses high-quality, sustainable materials in their construction processes, ensuring that buildings are not only robust but also environmentally friendly.

The Construction Process at Lida Group

1. Prefabrication

One of the key advantages of working with Lida Group is their emphasis on prefabrication:

- Off-Site Manufacturing: Many components of the steel structures are manufactured off-site in a controlled environment, which ensures precision and reduces waste. This method also accelerates the overall construction timeline.

- Quality Control: Lida Group implements strict quality control measures during the prefabrication process, ensuring that each component meets the highest standards before being transported to the construction site.

2. On-Site Assembly

Once the prefabricated components reach the construction site, the assembly process begins:

- Skilled Labor: Lida Group employs skilled workers who are experienced in steel construction, ensuring that assembly is completed efficiently and safely.

- Rapid Installation: The modular nature of steel structures allows for quick installation, minimizing downtime and disruptions to the client’s operations.

3. Final Touches and Adjustments

After the main structure is assembled, Lida Group focuses on the finishing touches:

- Custom Features: Clients can choose from a variety of custom features, such as insulation, cladding, and roofing options, to enhance the functionality and aesthetics of the building.

- Compliance and Inspections: Lida Group ensures that all structures comply with local building codes and regulations, conducting thorough inspections before handing over the completed project to the client.

Case Studies: Successful Projects by Lida Group

Case Study 1: Manufacturing Facility

Lida Group was approached by a manufacturing company looking to expand its operations. The project involved:

- Custom Design: Lida Group designed a steel structure that included large open spaces for machinery and workflow optimization.

- Prefabrication and Rapid Assembly: The prefabricated components were manufactured and delivered on-site, allowing for a quick assembly that minimized operational downtime.

- Positive Results: The new facility increased production capacity and efficiency, significantly contributing to the company’s growth.

Case Study 2: Agricultural Workshop

An agricultural business sought to build a workshop for equipment maintenance and repair. Lida Group provided:

- Tailored Solutions: The workshop was designed to accommodate specific tools and machinery, optimizing space for different tasks.

- Durable Materials: The use of high-quality steel ensured that the workshop would withstand the rigors of agricultural use.

- Enhanced Efficiency: The customized workshop allowed for more streamlined operations, leading to improved productivity in the agricultural business.

The Future of Steel Structures

1. Growing Demand for Customization

As industries evolve, the demand for customized steel structures will continue to rise. Businesses are increasingly looking for solutions that meet their specific operational needs while also aligning with sustainability goals.

2. Technological Advancements

Innovations in construction technology will further enhance the capabilities of steel structure buildings:

- Smart Building Technologies: The integration of smart technologies, such as IoT devices and automated systems, will enable more efficient building management and energy use.

- Advanced Materials: The development of new materials, such as high-strength steel and eco-friendly coatings, will improve the performance and sustainability of steel structures.

3. Focus on Sustainability

The construction industry is shifting towards more sustainable practices, and Lida Group is committed to leading this change:

- Eco-Friendly Practices: Implementing sustainable practices throughout the construction process, from material sourcing to waste management, will become increasingly important.

- Energy Efficiency: Future steel structures will incorporate energy-efficient designs and systems, reducing their carbon footprint and operational costs.

Conclusion

Lida Group stands as a beacon of innovation and customization in the realm of steel structure buildings and workshops. By prioritizing client needs and leveraging advanced technology, Lida Group is reshaping the construction industry with tailored solutions that meet the demands of modern businesses.

The advantages of steel structures—durability, flexibility, cost-effectiveness, and sustainability—make them the ideal choice for a wide range of applications. As industries continue to evolve, Lida Group remains committed to providing high-quality, customized steel structure solutions that empower businesses to thrive.

Whether you’re looking to build a manufacturing facility, a workshop, or any other type of steel structure, Lida Group is your go-to partner. With a focus on quality, innovation, and customer satisfaction, Lida Group is ready to help you realize your vision and build a successful future.

Contact Us

Post time: Feb-05-2025