Introduction

The world of industrial construction is continually evolving, with steel structure workshops at the forefront of this transformation. As businesses seek to optimize efficiency, sustainability, and functionality, innovative design trends are emerging in the construction of steel workshops. These trends not only enhance the performance of the structures but also ensure that they meet the dynamic needs of modern industries. This article explores the latest design trends in steel structure workshops, focusing on modularity, sustainability, smart technology integration, flexibility, and aesthetic considerations.

Understanding Steel Structure Workshops

What Are Steel Structure Workshops?

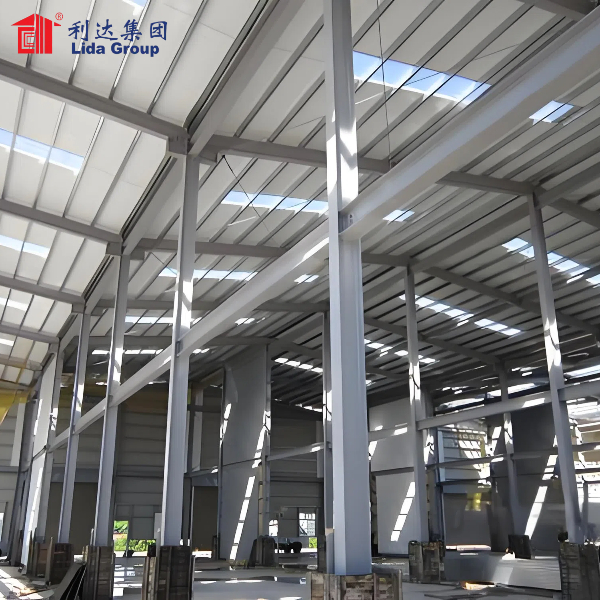

Steel structure workshops are buildings primarily made from steel components, designed for various industrial applications. These workshops serve multiple purposes, including manufacturing, assembly, maintenance, and storage. The use of steel in construction offers numerous advantages, including strength, durability, and flexibility, making it an ideal choice for industrial environments.

The Importance of Innovative Design

As industries evolve, the demands placed on workshops change. Innovative design is crucial for addressing the following:

- Increased Efficiency: Workshops must facilitate streamlined operations, from material handling to production processes.

- Sustainability Goals: With growing environmental concerns, workshops need to incorporate sustainable practices and materials.

- Adaptability: Businesses require spaces that can evolve with their operational needs, accommodating changes in technology and workflow.

Key Design Trends in Steel Structure Workshops

1. Modular Design

Modular design is one of the most significant trends in steel structure workshops. This approach involves creating pre-fabricated modules that can be easily assembled and reconfigured on-site.

Benefits of Modular Design

- Flexibility: Modular workshops can be expanded or modified as business needs change, allowing companies to adapt quickly to market demands.

- Reduced Construction Time: Off-site fabrication speeds up the construction process, minimizing downtime and allowing businesses to begin operations sooner.

- Cost-Effectiveness: By reducing labor and material waste, modular designs can lead to significant cost savings.

2. Sustainable Practices

Sustainability is no longer an option but a necessity in modern construction. Steel structure workshops are increasingly incorporating eco-friendly practices and materials.

Key Sustainable Practices

- Recycled Steel: Utilizing recycled steel reduces the environmental impact of new construction and promotes a circular economy.

- Energy-Efficient Designs: Workshops are being designed with energy-efficient systems, including advanced insulation, natural lighting, and renewable energy sources such as solar panels.

- Water Conservation: Incorporating rainwater harvesting systems and efficient plumbing can significantly reduce water usage in industrial operations.

Case Study: Green Steel Workshops

Several companies have successfully implemented sustainable practices in their steel workshops. For example, a leading manufacturer in the automotive sector integrated renewable energy systems and used recycled materials in their new steel workshop, resulting in a 30% reduction in energy costs.

3. Smart Technology Integration

The integration of smart technologies is transforming how steel structure workshops operate. These technologies enhance efficiency, safety, and overall performance.

Features of Smart Workshops

- IoT Devices: Internet of Things (IoT) devices can monitor equipment performance, track materials, and optimize workflows in real-time.

- Automated Systems: Automation in inventory management, material handling, and production processes reduces labor costs and increases efficiency.

- Data Analytics: Utilizing data analytics tools allows businesses to gain insights into operational performance, enabling data-driven decision-making.

4. Flexible and Adaptive Spaces

Modern steel structure workshops are designed to be flexible and adaptable, accommodating various functions and workflows.

Design Elements for Flexibility

- Open Floor Plans: Eliminating unnecessary walls allows for versatile use of space, enabling easy reconfiguration as operational needs change.

- Multi-Use Areas: Designing spaces that can serve multiple purposes—such as assembly, storage, and office functions—maximizes efficiency.

- Movable Walls: Implementing movable or demountable walls allows for quick reconfiguration of space to meet changing demands.

5. Aesthetic Considerations

While functionality is paramount, the aesthetic appeal of steel structure workshops is gaining importance. Modern designs emphasize not only practicality but also visual appeal.

Aesthetic Design Trends

- Architectural Features: Incorporating architectural elements such as glass facades, natural materials, and modern finishes can enhance the workshop’s appearance and create a welcoming environment.

- Landscaping: Thoughtful landscaping around steel workshops can improve aesthetics and create a pleasant working environment for employees.

- Branding Opportunities: Customizable exterior designs allow businesses to showcase their brand identity, making the workshop a reflection of their corporate values.

6. Enhanced Safety Features

Safety is a critical consideration in the design of steel structure workshops. Innovative design trends focus on enhancing safety for workers and equipment.

Safety Innovations

- Advanced Fire Protection Systems: Incorporating modern fire detection and suppression systems ensures the safety of both personnel and property.

- Ergonomic Design: Designing workspaces with ergonomics in mind minimizes the risk of injury and enhances worker comfort.

- Improved Access Control: Implementing smart access control systems enhances security and ensures that only authorized personnel can access sensitive areas.

The Construction Process

1. Planning and Design

The design phase is crucial for the success of steel structure workshops. Key considerations include:

- Site Assessment: Evaluating the construction site helps identify potential challenges and opportunities for optimization.

- Collaboration with Stakeholders: Engaging with stakeholders—including clients, architects, and engineers—ensures that the design meets all requirements and expectations.

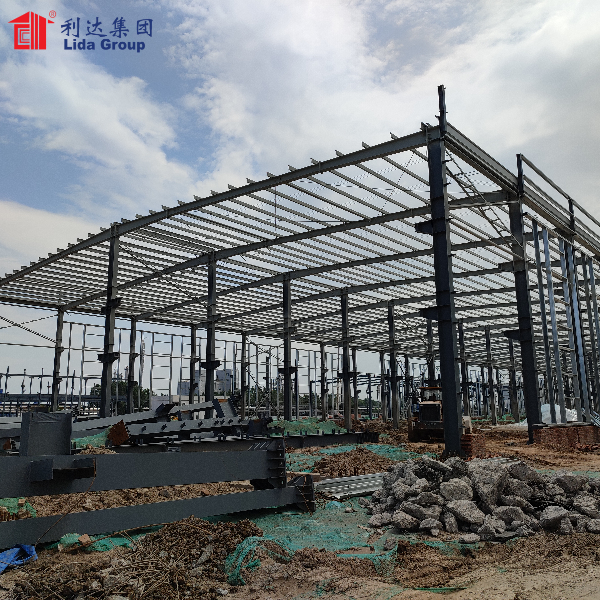

2. Prefabrication

Prefabrication involves manufacturing components off-site, allowing for higher quality and efficiency:

- Quality Control: Fabricating components in a controlled environment ensures precision and reduces on-site errors.

- Logistics Planning: Coordinating transportation of prefabricated components to the construction site minimizes delays.

3. On-Site Assembly

Once components arrive on-site, the assembly process begins:

- Rapid Construction: Skilled teams assemble the steel structure quickly, utilizing cranes and other equipment to position components accurately.

- Final Inspections: Conducting thorough inspections ensures that the structure meets safety and quality standards before operations begin.

Real-World Applications of Innovative Steel Workshops

1. Manufacturing Facilities

Innovative steel structure workshops are widely used in manufacturing:

- Production Lines: Flexible designs accommodate various production lines, allowing for efficient workflows.

- Quality Control Areas: Dedicated spaces for quality control ensure that products meet industry standards.

2. Logistics and Distribution Centers

In logistics, steel structure workshops play a vital role:

- Scalable Storage Solutions: Modular designs allow for easy expansion as inventory needs change.

- Efficient Sorting and Distribution: Ergonomic layouts facilitate efficient sorting and distribution processes.

3. Research and Development Centers

Steel workshops are increasingly being used for research and development:

- Collaborative Spaces: Open designs foster collaboration among teams, enhancing innovation and creativity.

- Flexible Lab Areas: Laboratories can be designed to accommodate various research activities and easily reconfigured as needed.

4. Agricultural Storage Facilities

In agriculture, steel workshops provide essential storage solutions:

- Equipment Storage: Durable structures protect valuable equipment from the elements.

- Crop Storage: Climate-controlled environments ensure the safe storage of crops, reducing spoilage.

Future Trends in Steel Structure Workshops

1. Increased Use of Automation

As technology advances, the use of automation in steel structure workshops will continue to rise:

- Robotic Systems: Robotics will enhance efficiency in material handling, assembly, and inspection processes.

- Automated Inventory Management: Smart systems will streamline inventory management, reducing the risk of errors and improving accuracy.

2. Emphasis on Resilience

The need for resilience in the face of climate change and other challenges will drive future design trends:

- Disaster-Resistant Designs: Workshops will be designed to withstand extreme weather events, ensuring business continuity.

- Integrated Sustainability: Future designs will increasingly incorporate sustainable practices, addressing both operational efficiency and environmental impact.

3. Customization and Personalization

The demand for tailored solutions will continue to grow:

- Client-Specific Designs: Workshops will be designed to meet the unique needs of individual clients, enhancing functionality and efficiency.

- Modular Add-Ons: The ability to add features and functionalities over time will become increasingly important for businesses looking to future-proof their investments.

Conclusion

Innovative design trends in steel structure workshops are reshaping the landscape of industrial construction. By focusing on modularity, sustainability, smart technology integration, flexibility, and aesthetic considerations, businesses can create workshops that not only meet their operational needs but also enhance employee well-being and environmental sustainability.

As industries evolve and new challenges arise, the importance of innovative design in steel structure workshops will only continue to grow. By embracing these trends, companies can position themselves for success in an increasingly competitive market, ensuring that their workshops remain efficient, adaptable, and resilient for years to come. Lida Group and similar leaders in the industry will play a crucial role in driving these innovations, transforming the future of steel structure workshops and setting new standards for excellence in industrial construction.

Contact Us

Post time: Dec-07-2024