Introduction

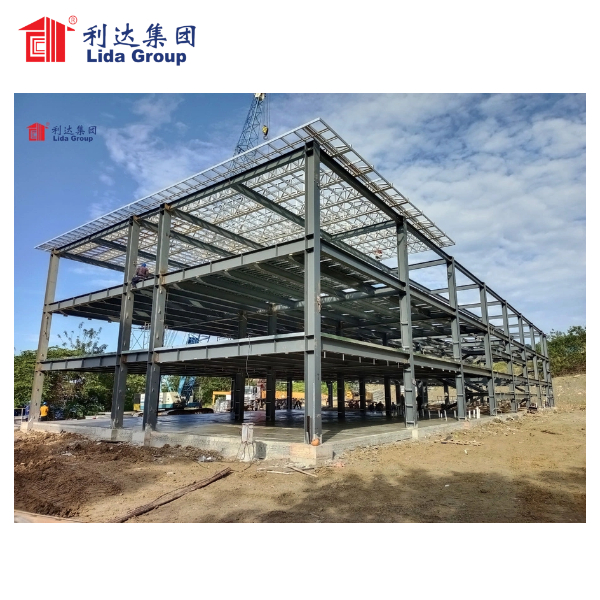

In an era of rapid technological advancement and environmental awareness, businesses face unprecedented challenges and opportunities. The need for flexible, durable, and sustainable infrastructure has never been more crucial. Steel structures have emerged as a leading solution, providing the resilience and adaptability that modern enterprises require. Lida Group, a pioneer in steel structure manufacturing, has established itself as a key player in this field, offering innovative solutions that not only meet current demands but also anticipate future needs. This article explores how Lida Group’s steel structures can help businesses future-proof their operations, enhance efficiency, and promote sustainability.

Understanding Future-Proofing

What Does Future-Proofing Mean?

Future-proofing refers to the strategies and practices that organizations implement to ensure their long-term viability and adaptability in a changing environment. It encompasses a variety of considerations, including:

- Technological Adaptability: The ability to integrate new technologies seamlessly into existing systems.

- Sustainability: Implementing environmentally friendly practices that align with global sustainability goals.

- Flexibility: Designing infrastructure that can be easily modified or expanded as business needs evolve.

The Importance of Future-Proofing

- Resilience Against Market Changes: Businesses that are well-prepared for change can respond more effectively to market fluctuations and disruptions.

- Cost Efficiency: Future-proofed infrastructure often leads to lower operational costs over time through efficiency gains and reduced maintenance needs.

- Competitive Advantage: Companies that invest in adaptable and sustainable practices are more likely to attract customers and retain talent.

The Role of Steel Structures in Future-Proofing

1. Durability and Longevity

Steel structures are renowned for their durability, making them an excellent choice for future-proofing business infrastructure.

a. Strength and Resilience

- Load-Bearing Capacity: Steel’s high strength-to-weight ratio allows for larger spans and structures that can support heavy loads, making it suitable for warehouses, manufacturing facilities, and other industrial applications.

- Weather Resistance: Steel is inherently resistant to many environmental factors, including rust, pests, and rot, ensuring longevity and reducing the need for frequent repairs.

b. Low Maintenance Requirements

Unlike traditional materials such as wood or concrete, steel structures typically require less maintenance, leading to cost savings and less downtime for businesses.

2. Flexibility in Design

One of the key advantages of steel structures is their inherent flexibility.

a. Modular Design

- Adaptable Layouts: Lida Group’s modular design approach allows for quick reconfiguration of spaces, enabling businesses to adapt to changing operational needs without extensive renovations.

- Scalability: As businesses grow, modular steel structures can be easily expanded to accommodate additional functions or increased capacity.

b. Customization

Lida Group offers customized solutions tailored to specific industry requirements, allowing businesses to create spaces that align with their unique operational needs.

3. Technological Integration

Steel structures can easily incorporate advanced technologies, making them ideal for future-proofing.

a. Smart Building Technologies

- IoT Integration: Lida Group designs buildings with the capability to integrate Internet of Things (IoT) devices, enabling real-time monitoring of systems such as lighting, HVAC, and security.

- Automation Systems: Incorporating automated systems for inventory management, climate control, and resource allocation can enhance operational efficiency.

b. Energy Management

Steel structures can be designed to support renewable energy systems, such as solar panels and energy-efficient HVAC systems, facilitating a shift towards sustainable operations.

Sustainability as a Core Component

1. Eco-Friendly Materials

Lida Group prioritizes sustainability by utilizing recyclable materials in its steel structures.

a. Steel Recycling

- Circular Economy: Steel is one of the most recycled materials globally. Lida Group emphasizes the use of recycled steel in their projects, reducing the environmental impact and promoting a circular economy.

b. Sustainable Sourcing

- Responsible Procurement: Lida Group sources materials from suppliers who adhere to sustainable practices, ensuring that the entire supply chain supports environmental goals.

2. Energy Efficiency

Designing energy-efficient buildings is essential for reducing operational costs and environmental impact.

a. Natural Light Optimization

- Large Windows and Skylights: Incorporating ample natural light reduces reliance on artificial lighting, resulting in lower energy consumption and a healthier work environment.

b. Insulation and Climate Control

- Advanced Insulation Techniques: Steel structures can be designed with high-quality insulation materials to maintain optimal temperatures, further enhancing energy efficiency.

3. Green Certifications

Many of Lida Group’s steel structures are designed to meet or exceed green building standards, such as LEED (Leadership in Energy and Environmental Design) certification, which can enhance a business’s reputation and marketability.

Real-World Applications of Lida Group’s Steel Structures

Case Study 1: E-Commerce Distribution Center

Overview: Lida Group designed a highly efficient distribution center for a leading e-commerce company.

Key Features:

- Modular Design: The facility was constructed with modular components, allowing for easy expansion as the business grew.

- Energy Efficiency: The building incorporated energy-efficient lighting and insulation, reducing operating costs.

Results: The distribution center significantly improved operational efficiency, reducing order processing times by 30% while aligning with sustainability goals.

Case Study 2: Manufacturing Facility

Overview: A major automotive manufacturer partnered with Lida Group to build a state-of-the-art production facility.

Key Features:

- Flexible Layout: The design allowed for quick reconfiguration based on production needs.

- Smart Technologies: The facility integrated IoT devices for real-time monitoring of production lines.

Results: The facility increased production capacity by 25% while minimizing downtime and enhancing overall efficiency.

Case Study 3: Agricultural Storage Facility

Overview: Lida Group constructed a storage facility for a large agricultural operation focused on climate control and durability.

Key Features:

- Weather-Resistant Materials: The building was designed to withstand harsh environmental conditions.

- Ventilation Systems: Advanced ventilation systems were incorporated to regulate temperature and humidity for stored crops.

Results: The facility provided a secure and climate-controlled environment, enhancing operational efficiency during peak seasons.

The Future of Steel Structures

1. Innovations in Materials and Technology

The future of steel structures will be shaped by advancements in materials and technology:

- High-Performance Steel: Innovations in steel manufacturing will lead to stronger, lighter materials that can further enhance design flexibility and energy efficiency.

- Smart Materials: The integration of smart materials that can respond to environmental changes will revolutionize building design and functionality.

2. Increased Automation and Robotics

As industries continue to embrace automation, steel structures will evolve to accommodate these technologies:

- Automated Systems: Future steel structures will incorporate more automated systems for inventory management, climate control, and security.

- Robotics Integration: Facilities will increasingly utilize robotics for material handling and production processes, enhancing operational efficiency.

3. Continued Focus on Sustainability

Sustainability will remain a key focus in the development of steel structures:

- Carbon Neutrality Goals: The construction industry is moving towards carbon neutrality, and steel structures will play a crucial role in achieving these targets through sustainable practices and materials.

- Green Certifications: As demand for green buildings grows, more steel structures will be designed to meet rigorous environmental standards.

Conclusion

Future-proofing your business requires a proactive approach to infrastructure design, focusing on durability, flexibility, and sustainability. Lida Group’s steel structures offer a compelling solution, combining innovative design with advanced technologies to meet the evolving needs of modern enterprises.

By investing in steel structures, businesses can enhance their operational efficiency, reduce costs, and position themselves to thrive in an ever-changing market. With Lida Group as a partner, organizations can confidently navigate the future, knowing they have a resilient and adaptable foundation to support their growth and success.

As industries evolve and new challenges arise, Lida Group will continue to lead the way in steel structure manufacturing, delivering solutions that not only meet current demands but also anticipate future opportunities. Embracing steel structures is not just a choice; it is a strategic move towards a sustainable and prosperous future.

Contact Us

Post time: Dec-10-2024