In the fast-paced world of modern business, efficiency and productivity are paramount. As industries evolve, the demand for flexible and functional workspaces has grown significantly. Prefabricated workshops have emerged as a viable solution, offering customizable designs that cater to the specific needs of various sectors. Lida Group, a leader in the prefabricated construction industry, has developed innovative workshop solutions that enhance productivity while maintaining a focus on quality and sustainability. This article explores the benefits of Lida Group’s customizable prefab workshops, their design features, and their impact on productivity in various industries.

Understanding Prefabricated Workshops

What Are Prefabricated Workshops?

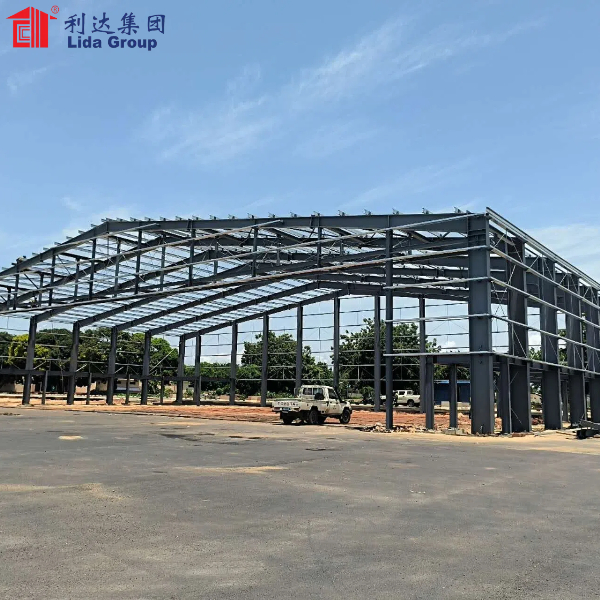

Prefabricated workshops are structures that are manufactured off-site in a controlled environment and then transported to the desired location for assembly. This method contrasts with traditional construction, where buildings are constructed entirely on-site. Prefab workshops can serve a variety of purposes, from manufacturing and assembly to storage and research facilities.

Key Characteristics of Prefabricated Workshops

- Modular Design: Prefabricated workshops are often modular, allowing for easy customization and expansion based on the specific needs of the business.

- Speed of Construction: These workshops can be assembled in a fraction of the time required for traditional buildings, enabling businesses to start operations quickly.

- Cost-Effectiveness: Prefab construction often results in lower labor and material costs, making it an attractive option for businesses looking to optimize their budgets.

- Quality Control: Building in a factory setting allows for rigorous quality checks, ensuring that the final product meets high standards.

- Sustainability: Many prefab workshops incorporate eco-friendly materials and energy-efficient designs, contributing to a smaller environmental footprint.

The Benefits of Lida Group’s Customizable Prefab Workshops

Lida Group’s prefab workshops offer numerous advantages that can significantly enhance productivity for businesses across various sectors.

1. Customization Options

One of the most significant benefits of Lida Group’s prefab workshops is their ability to be customized according to the specific needs of the business.

- Flexible Layouts: Lida Group offers a variety of floor plans that can be tailored to accommodate different workflows and operational requirements. Whether it’s an open space for collaborative work or designated areas for machinery, businesses can design a layout that promotes efficiency.

- Scalable Solutions: As businesses grow, their needs may change. Lida Group’s modular designs allow for easy expansion by adding additional modules, ensuring that the workspace can evolve with the company.

2. Enhanced Efficiency

The design and construction of Lida Group’s prefab workshops are geared towards maximizing efficiency.

- Streamlined Operations: The customizable layouts can be designed to minimize movement and optimize workflows, which can lead to increased productivity. For example, placing equipment and workstations strategically can reduce unnecessary steps and improve overall efficiency.

- Quick Setup: The speed of construction means that businesses can occupy their new workshops much sooner than traditional builds would allow. This rapid deployment is crucial for companies looking to minimize downtime and start operations quickly.

3. Cost Savings

Lida Group’s prefab workshops provide significant cost advantages, which can enhance a company’s overall productivity.

- Lower Construction Costs: The efficiency of factory production reduces labor and material costs, making it a cost-effective solution for businesses. These savings can be redirected towards other operational needs, such as staffing or equipment.

- Reduced Operating Costs: Many of Lida Group’s workshops are designed with energy-efficient features, helping businesses save on utility bills. Features like high-quality insulation and energy-efficient lighting contribute to lower operating expenses.

4. Quality Assurance

Quality is a hallmark of Lida Group’s prefab workshops, ensuring that businesses receive a durable and reliable product.

- Consistent Standards: Manufacturing in a controlled environment allows for rigorous quality control, ensuring that each component meets high standards. This consistency translates into fewer repairs and maintenance issues down the line.

- Durable Materials: Lida Group uses high-quality materials that are built to withstand the demands of industrial use, providing businesses with a long-lasting workspace.

5. Sustainability

Lida Group is committed to promoting sustainable practices through its prefab workshops, which can enhance a company’s reputation and appeal.

- Eco-Friendly Materials: The use of sustainable materials in construction helps minimize the environmental impact of the building process. This commitment to sustainability can resonate with customers and clients who prioritize eco-friendly practices.

- Energy Efficiency: Many of Lida Group’s workshops incorporate energy-efficient systems and renewable energy options, allowing businesses to reduce their carbon footprint and operating costs. This not only benefits the environment but also positions companies as responsible corporate citizens.

6. Versatility of Use

The versatility of Lida Group’s prefab workshops makes them suitable for a wide range of applications.

- Manufacturing and Production: These workshops can be designed to accommodate various manufacturing processes, providing the necessary space for equipment, assembly lines, and storage.

- Research and Development: Companies in the tech or pharmaceutical sectors can use Lida Group’s workshops as dedicated R&D facilities, equipped with specialized labs and workspaces.

- Storage Solutions: For businesses that require significant storage space, Lida Group’s workshops can be configured to provide efficient storage solutions, including shelving, pallet racking, and climate-controlled areas.

7. Community and Collaboration

Lida Group’s prefab workshops can foster a sense of community and collaboration among employees.

- Open Spaces for Collaboration: The customizable layouts can include open areas that encourage teamwork and collaboration among employees. This can lead to increased creativity and innovation within the workforce.

- Dedicated Zones for Different Functions: By creating designated areas for specific functions, businesses can enhance communication and streamline operations. For example, separating production areas from administrative offices can reduce distractions and improve focus.

Design Innovations in Lida Group’s Prefab Workshops

1. Modern Aesthetics

Lida Group’s prefab workshops are designed not only for functionality but also for visual appeal.

- Contemporary Designs: The architectural styles reflect modern trends, appealing to businesses that wish to project a contemporary image. Clean lines and innovative materials create inviting workspaces that enhance the overall work environment.

- Customization of Finishes: Businesses can choose from a range of interior and exterior finishes to create a workspace that aligns with their brand identity and values.

2. Efficient Use of Space

Lida Group emphasizes maximizing space utilization in their designs.

- Smart Layouts: Modular designs are crafted to make the most of the available space, ensuring that every square foot serves a purpose. This efficiency is crucial for businesses looking to optimize their operations.

- Multi-Functional Areas: Many workshops can include multi-purpose spaces that adapt to various functions, such as training rooms that can convert into meeting spaces as needed.

3. Integration of Technology

Lida Group incorporates advanced technology into their prefab workshops to enhance functionality and efficiency.

- Smart Building Features: Many of their workshops come equipped with smart systems that allow businesses to monitor and manage energy consumption, security, and environmental conditions remotely.

- Sustainable Technologies: The option to install renewable energy systems, such as solar panels, further supports sustainable practices and reduces reliance on traditional energy sources.

Applications of Lida Group’s Prefab Workshops

Lida Group’s prefab workshops can be applied across various sectors, each with unique requirements.

1. Manufacturing

Manufacturing companies benefit significantly from Lida Group’s customizable workshops.

- Production Facilities: Modular workshops can be designed to accommodate assembly lines, equipment, and storage areas, providing a comprehensive solution for manufacturing needs.

- Quality Control Areas: Dedicated spaces for quality assurance and testing can be integrated into the design, ensuring that products meet industry standards.

2. Research and Development

Companies in tech and pharmaceuticals require specialized facilities for R&D.

- Laboratories: Lida Group’s workshops can be configured to include labs equipped with specialized equipment, ensuring that companies have the necessary space for innovation.

- Collaboration Spaces: Open areas for brainstorming and collaboration can enhance creativity and teamwork among R&D teams.

3. Educational Institutions

Educational facilities can also benefit from Lida Group’s prefab workshops.

- Training Centers: These workshops can serve as vocational training centers, providing hands-on learning environments for students in various trades.

- Community Education: They can also be used for community education programs, offering flexible learning spaces for workshops and seminars.

4. Retail and Showrooms

Retail businesses can utilize Lida Group’s workshops as showrooms or retail spaces.

- Flexible Displays: The modular nature of these workshops allows for flexible display options, accommodating different product layouts and promotional events.

- Customer Engagement Areas: Spaces can be designed to enhance customer interaction, with areas for demonstrations and consultations.

5. Emergency Response

In times of crisis, Lida Group’s prefab workshops can be deployed quickly for emergency response.

- Temporary Shelters: These workshops can be converted into temporary shelters for disaster relief, providing essential living and working spaces for first responders.

- Mobile Units: For situations requiring rapid deployment, Lida Group can provide mobile units that can be transported to the site of an emergency.

The Implementation Process of Lida Group’s Prefab Workshops

1. Planning and Consultation

The implementation process begins with thorough planning and consultation.

- Needs Assessment: Understanding the specific requirements of the business is crucial for developing effective solutions. Lida Group works closely with clients to identify their needs and objectives.

- Stakeholder Engagement: Engaging with stakeholders, including employees and local authorities, ensures that designs align with community preferences and regulations.

2. Designing the Prefab Workshops

Selecting an appropriate design is essential for success.

- Custom Modular Solutions: Lida Group offers a variety of modular designs tailored to different needs and preferences, allowing clients to choose layouts that fit their vision.

- Compliance with Regulations: Ensuring that designs comply with local building codes and regulations is vital for a smooth implementation process.

3. Manufacturing and Prefabrication

Once designs are finalized, the manufacturing process begins.

- Production of Units: Prefab workshops are manufactured in a controlled environment, ensuring high quality and consistency throughout the construction process.

- Quality Control: Each unit undergoes rigorous quality checks to meet industry standards and specifications, ensuring durability and reliability.

4. Site Preparation

While the units are being fabricated, site preparation takes place.

- Clearing and Grading: The site is cleared of obstacles and graded to ensure a level foundation for the workshops.

- Foundation Construction: A strong foundation may be laid, depending on the site conditions and intended use of the prefabricated units.

5. Assembly

The assembly phase is where the prefab workshops come together.

- Erection of Units: The modular units are assembled on-site, often using cranes or other lifting equipment for efficiency.

- Installation of Utilities: Electrical, plumbing, and HVAC systems are installed to ensure the workshops are fully operational and comfortable for occupants.

6. Finishing Touches

After the main structure is complete, finishing touches are added.

- Interior Layout: Additional features such as workstations, storage areas, and break rooms are constructed according to the design specifications.

- Exterior Finishing: The exterior of the units may be finished with weather-resistant materials to ensure durability and aesthetic appeal.

7. Final Inspection and Handover

Before the workshops are handed over to clients, a final inspection is conducted.

- Quality Assurance: Thorough checks ensure that all aspects of the prefab workshops meet quality standards and regulatory compliance.

- Client Walkthrough: A walkthrough with the client allows for any last-minute adjustments or modifications to be made.

Case Studies: Successful Implementations of Lida Group’s Prefab Workshops

Case Study 1: Manufacturing Facility

Challenge: A manufacturing company needed a new facility to expand production quickly.

Solution: Lida Group provided a customizable prefab workshop designed to accommodate assembly lines and storage.

Outcome: The facility was completed in record time, allowing the company to increase production capacity and meet market demands.

Case Study 2: Research and Development Center

Challenge: A tech company required a dedicated space for R&D to innovate new products.

Solution: Lida Group designed a modular workshop with specialized labs and collaborative spaces.

Outcome: The new R&D center enhanced the company’s innovation capabilities and facilitated teamwork among researchers.

Case Study 3: Emergency Response Shelter

Challenge: Following a natural disaster, immediate shelter was needed for displaced residents.

Solution: Lida Group deployed prefab workshops as temporary shelters for affected individuals.

Outcome: The rapid response provided safe and secure accommodations, helping families regain stability during a challenging time.

The Future of Prefabricated Workshops

Technological Innovations

The future of prefabricated workshops will be shaped by ongoing technological advancements.

- Smart Building Solutions: Incorporating IoT devices into prefab workshops can enhance monitoring and management of energy usage, security, and environmental conditions.

- Data-Driven Design: Utilizing data analytics to inform design and operational decisions can lead to more efficient and effective work environments.

Growing Popularity

The popularity of prefab workshops is on the rise, particularly among industries seeking flexible and efficient workspace solutions. Lida Group is well-positioned to meet this demand, expanding its offerings and exploring new markets.

Focus on Sustainability

As environmental concerns continue to drive the demand for sustainable solutions, Lida Group’s commitment to eco-friendly practices and materials will resonate with businesses that prioritize sustainability in their operations.

Global Market Potential

The demand for prefabricated workshops is expected to grow globally, particularly in regions experiencing rapid industrialization and urbanization. Lida Group aims to expand its reach, providing innovative solutions to meet the needs of diverse markets.

Conclusion

Lida Group‘s customizable prefab workshops represent a transformative approach to modern workspaces. By prioritizing flexibility, efficiency, and sustainability, Lida Group is addressing the needs of businesses seeking to enhance productivity and optimize their operations. The versatility of these workshops makes them suitable for a variety of applications, from manufacturing and research to emergency response.

As industries continue to evolve, Lida Group’s commitment to innovation positions them as a leader in the prefab construction movement. Through their focus on creating high-quality, customizable workspaces, Lida Group is not just building workshops; they are building a more productive and sustainable future for businesses worldwide. The rise of prefabricated workshops is a testament to the potential of modern construction methods to meet the dynamic needs of the global economy.

Contact Us

Post time: Apr-22-2025