Introduction:

Poultry farming is an industry that demands constant innovation to meet the growing demands for food production, animal welfare, and sustainability. Lida Group‘s steel structures have emerged as a game-changer in the poultry farming landscape, revolutionizing the way poultry farm houses are designed, constructed, and operated. This article explores the construction innovation brought by Lida Group’s steel structures and the significant impact they have on poultry farming, including advancements in construction efficiency, modularity, environmental sustainability, and animal welfare.

- Construction Efficiency:

a) Prefabrication and Modular Construction: Lida Group’s steel structures are prefabricated off-site, allowing for faster and more efficient construction compared to traditional building methods. The components are manufactured in a controlled environment, ensuring high-quality standards and reducing on-site construction time. The modular nature of steel structures enables easy assembly and disassembly, facilitating rapid deployment and flexibility for poultry farmers.

b) Streamlined Construction Process: The use of steel structures eliminates the need for extensive on-site fabrication and reduces the dependency on skilled labor. The simplified construction process minimizes project delays, enhances productivity, and lowers overall construction costs. Poultry farmers can benefit from reduced downtime and faster time-to-market for their operations.

c) Construction in Challenging Locations: Steel structures offer versatility in construction, making it possible to build poultry farm houses in challenging locations. Whether it’s uneven terrain, remote areas, or limited access sites, Lida Group’s steel structures can be designed and engineered to meet the specific requirements, enabling poultry farmers to optimize land usage and expand their operations to previously untapped locations.

- Modularity and Scalability:

a) Flexible Design and Expansion: Lida Group’s steel structures provide poultry farmers with the flexibility to design farm houses that cater to their specific needs and preferences. The modular components allow for easy expansion or modification as the farm grows or operational requirements change. Poultry farmers can scale their operations without significant disruptions, minimizing the impact on existing infrastructure.

b) Multi-Purpose Usage: Steel structures offer versatility beyond poultry farm houses. The modular design allows for the integration of additional spaces, such as storage areas, offices, or processing facilities, within the same structure. This multi-purpose usage enhances operational efficiency and maximizes the utilization of available space.

c) Portability and Reusability: Lida Group’s steel structures are designed to be portable and reusable. In situations where land leases or relocation are necessary, the steel structures can be disassembled and relocated to a new site, reducing the need for new construction. This portability ensures long-term value and reduces environmental impact by minimizing construction waste.

- Environmental Sustainability:

a) Energy Efficiency: Lida Group’s steel structures can be designed with energy-efficient features, such as insulation, natural lighting, and renewable energy integration. These elements reduce energy consumption, lower carbon emissions, and contribute to a more sustainable poultry farming operation. Energy-efficient steel structures not only benefit the environment but also result in cost savings for poultry farmers in the long run.

b) Reduced Material Waste: Steel structures minimize material waste during construction due to their prefabrication process. The precise manufacturing of components ensures minimal scrap and optimized material usage. Additionally, steel is a highly recyclable material, allowing for the reuse and recycling of steel components at the end of their lifecycle, further reducing environmental impact.

c) Water Management: Lida Group’s steel structures can be designed to incorporate efficient water management systems, such as rainwater harvesting and water recycling. These systems reduce reliance on external water sources, promote water conservation, and enhance the overall sustainability of poultry farming operations.

- Animal Welfare and Farm Efficiency:

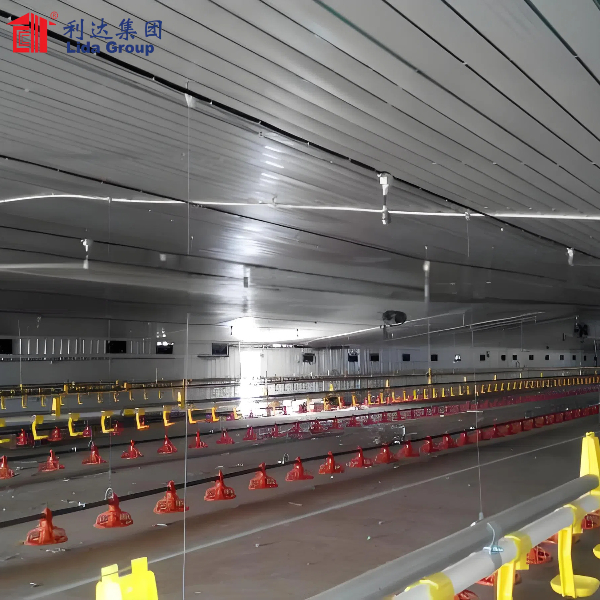

a) Enhanced Air Quality and Ventilation: Steel structures allow for efficient ventilation systems to be integrated, ensuring proper air circulation, removing harmful gases, and maintaining optimal air quality within the poultry farm house. Improved air quality reduces the risk of respiratory diseases, promotes the health and welfare of the poultry, and enhances overall farm productivity.

b) Biosecurity Measures: Steel structures offer advantages in implementing biosecurity measures to prevent disease outbreaks. The non-porous surfaces of steel are easy to clean and disinfect, reducing the risk of bacterial or viral contamination. Proper biosecurity protocols, coupled with the design flexibility of steel structures, facilitate the separation of different flocks or production areas, minimizing the spread of diseases.

c) Automation and Technology Integration: Lida Group’s steel structures provide an ideal framework for the integration of automation and technology in poultry farming operations. The open design and flexible layout allow for the seamless integration of automated feeding systems, climate control systems, and data monitoring technologies. These advancements improve operational efficiency, optimize feed conversion, and enable real-time monitoring of the poultry farm’s performance.

Conclusion:

Lida Group’s steel structures have brought significant construction innovation to the poultry farming landscape. The construction efficiency, modularity, environmental sustainability, and benefits to animal welfare provided by these steel structures have transformed the way poultry farm houses are designed, built, and operated. Poultryfarmers can now enjoy streamlined construction processes, scalability, and the ability to construct in challenging locations. The modular design allows for easy expansion and multi-purpose usage, while the portability and reusability of steel structures offer long-term value and reduce environmental impact.

Furthermore, Lida Group’s steel structures contribute to environmental sustainability through energy-efficient design, reduced material waste, and efficient water management. The improved air quality, ventilation systems, and biosecurity measures enhance animal welfare and farm efficiency. The integration of automation and technology in steel structures enables poultry farmers to optimize operations, monitor performance, and improve productivity.

Lida Group’s steel structures have revolutionized the poultry farming industry, providing innovative solutions that address the evolving needs of modern agriculture. With their construction efficiency, modularity, sustainability, and focus on animal welfare, these structures are shaping the future of poultry farming, enabling farmers to achieve greater efficiency, profitability, and sustainability in their operations.

Contact Us

Post time: Jul-05-2024