In recent years, the demand for coconut-based products has surged globally, driven by the growing awareness of their health benefits and versatility. This increase in demand has necessitated the establishment of efficient, modern coconut processing facilities. Lida Group, a leader in prefabricated construction, specializes in designing and constructing steel structures that cater specifically to the needs of coconut factories. This article explores the innovations in coconut factory design using steel structures, the numerous benefits of such facilities, and how Lida Group is contributing to the industry.

Understanding Coconut Processing

The Coconut Industry Landscape

Coconuts are not only a staple food in many tropical regions but also a significant source of economic activity. The coconut industry encompasses various products, including coconut oil, milk, water, fiber, and more. As consumer preferences shift towards natural and organic products, the demand for coconut-based goods continues to rise.

Key Processes in Coconut Factories

Coconut processing involves several key stages, each requiring specialized equipment and facilities:

- Receiving and Sorting: Fresh coconuts are received, sorted, and inspected for quality.

- Husking: The outer husk is removed to access the coconut shell.

- Shelling: The hard shell is cracked open to extract the coconut meat.

- Processing: The coconut meat is processed into various products, such as coconut milk, oil, and flour.

- Packaging: Final products are packaged for distribution.

To efficiently manage these processes, coconut factories must be designed with functionality and productivity in mind.

Benefits of Steel Structures for Coconut Factories

1. Durability and Strength

Steel structures offer exceptional durability, which is essential for coconut factories that handle heavy machinery and large volumes of raw materials:

- Weather Resistance: Steel frames withstand harsh weather conditions, protecting the factory from external damage and ensuring a safe working environment for employees.

- Longevity: Steel is resistant to rot, pests, and decay, significantly extending the lifespan of the factory compared to traditional materials.

2. Cost-Effectiveness

From a financial perspective, steel structures provide substantial savings throughout the lifecycle of the factory:

- Lower Construction Costs: The efficiency of prefabrication and reduced labor requirements lead to lower overall construction costs, making it an attractive option for investors.

- Long-Term Savings: The durability of steel structures results in lower maintenance costs, allowing businesses to allocate resources more effectively.

3. Speed of Construction

In the competitive coconut market, time is of the essence:

- Rapid Assembly: Steel components can be prefabricated off-site, allowing for quick assembly on-site. This rapid deployment enables businesses to start operations sooner.

- Concurrent Processes: While the steel components are being manufactured, site preparation can occur simultaneously, further reducing the overall construction timeline.

4. Flexibility and Customization

Lida Group’s steel structures are designed with flexibility in mind, accommodating the unique needs of coconut processing:

- Modular Design: The modular nature of steel construction allows for easy expansion and reconfiguration of the factory as operational needs change.

- Custom Layouts: Each factory can be tailored to optimize workflow, ensuring that processes are efficient and effective.

5. Environmental Sustainability

Sustainability is a growing concern in the construction industry, and steel structures can contribute to eco-friendly practices:

- Recyclable Materials: Steel is 100% recyclable, making it an environmentally friendly choice for construction projects. This not only reduces waste but also promotes a circular economy.

- Energy Efficiency: Steel factories can incorporate energy-efficient systems, such as solar panels and proper insulation, to minimize their carbon footprint.

Innovations in Coconut Factory Design

1. Integrated Processing Systems

Lida Group emphasizes the importance of integrated processing systems in coconut factories:

- Streamlined Operations: By designing factories that integrate multiple processing stages, Lida Group helps minimize the time and resources required for processing coconuts.

- Automated Machinery: Incorporating automated machinery into the design enhances efficiency and reduces labor costs, allowing for higher production rates.

2. Sustainable Water Management

Water management is crucial in coconut processing, where large quantities of water are required:

- Rainwater Harvesting: Sustainable designs can incorporate rainwater harvesting systems, reducing reliance on external water sources and promoting environmental responsibility.

- Wastewater Treatment: Advanced wastewater treatment systems can be integrated into the factory design, ensuring that any water used in processing is treated before being released back into the environment.

3. Energy-Efficient Designs

Lida Group prioritizes energy efficiency in its coconut factory designs:

- Natural Lighting: Factories can be designed to maximize natural light, reducing the need for artificial lighting and lowering energy consumption.

- Ventilation Systems: Effective ventilation systems help maintain a comfortable working environment while minimizing energy use.

4. Enhanced Storage Solutions

Efficient storage solutions are vital for managing raw materials and finished products:

- Vertical Storage: Steel structures can be designed with high ceilings, allowing for vertical storage solutions that maximize space and improve accessibility.

- Climate-Controlled Areas: Specific areas within the factory can be temperature-controlled to preserve the quality of coconut products.

The Construction Process of Steel Coconut Factories

1. Planning and Consultation

The construction of a coconut factory begins with a thorough planning and consultation phase:

- Needs Assessment: Lida Group collaborates with clients to understand their specific requirements, including production volumes, workflows, and sustainability goals.

- Site Analysis: Assessing the location for environmental factors, zoning regulations, and access to resources is crucial for successful planning.

2. Architectural Design

Once the planning phase is complete, Lida Group develops a comprehensive architectural design:

- Sustainable Design Principles: The design incorporates sustainable practices such as maximizing natural light, ventilation, and energy-efficient systems.

- Custom Layouts: Factories are designed to optimize operational workflows, ensuring that production processes are efficient and effective.

3. Prefabrication

Lida Group utilizes prefabrication techniques to streamline construction:

- Off-Site Manufacturing: Components of the factory are manufactured in a controlled environment, ensuring high quality and minimizing waste.

- Efficiency in Assembly: Prefabricated components can be quickly assembled on-site, significantly reducing construction time.

4. Site Preparation

While the factory components are being fabricated, site preparation takes place:

- Clearing and Grading: The site is cleared of obstacles and graded to ensure a level foundation for the factory.

- Foundation Construction: A strong foundation is laid to support the weight of the prefabricated structure.

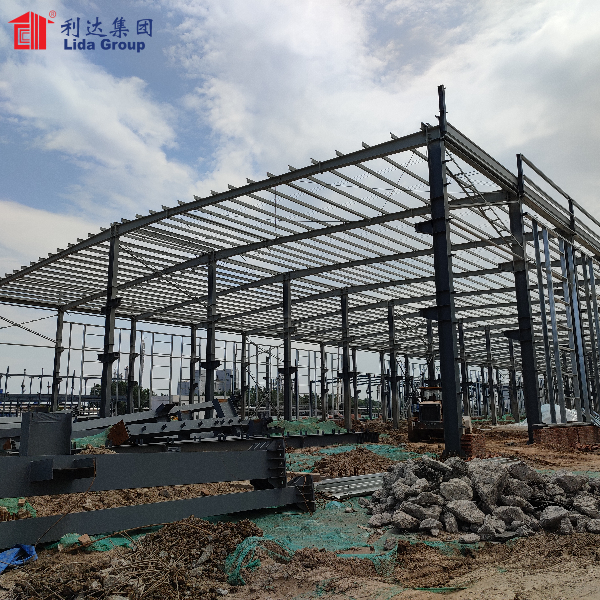

5. Assembly

The assembly phase is where the steel coconut factory begins to take shape:

- Erection of Steel Frames: The prefabricated steel frames are assembled on-site, often using cranes for heavy lifting.

- Installation of Roof and Walls: Once the framework is erected, the roof and wall panels are installed, providing the structural integrity needed for the factory.

6. Finishing Touches

After the main structure is complete, finishing touches are added:

- Interior Layout: Additional features such as processing areas, storage, and administrative offices are constructed according to the design specifications.

- Utilities Installation: Electrical, plumbing, and HVAC systems are installed to ensure the factory is fully operational.

7. Final Inspection and Handover

Before the factory is handed over to the client, a final inspection is conducted:

- Quality Assurance: Lida Group performs thorough checks to ensure that all aspects of the factory meet quality standards and regulatory compliance.

- Client Walkthrough: A walkthrough with the client allows for any last-minute adjustments or modifications.

Applications of Steel Coconut Factories

Steel coconut factories can be utilized across various sectors, each with unique requirements:

1. Coconut Oil Production

Coconut oil is one of the most popular products derived from coconuts:

- Efficient Processing: Steel structures can house the necessary machinery for extracting and refining coconut oil, ensuring high-quality production.

- Storage Solutions: These factories can also provide secure storage for raw materials and finished products, enhancing supply chain efficiency.

2. Coconut Water Bottling

As consumers increasingly seek healthy beverage options, coconut water has gained popularity:

- Bottling Facilities: Steel coconut factories can be equipped with bottling lines that streamline the production process and enhance product quality.

- Quality Control: The design can incorporate quality control measures to ensure that all coconut water products meet health and safety standards.

3. Coconut Milk and Cream Production

Coconut milk and cream are essential ingredients in many culinary applications:

- Processing Areas: Dedicated processing areas within steel structures can facilitate the production of coconut milk and cream, ensuring hygiene and efficiency.

- Customizable Layouts: The flexibility of steel construction allows for easy reconfiguration of space to accommodate changes in production methods or volumes.

4. Coconut Fiber Processing

Coconut fiber, or coir, is a valuable byproduct used in various applications:

- Fiber Extraction: Steel factories can be designed to process coconut husks for fiber extraction, contributing to sustainable resource utilization.

- Manufacturing Products: Factories can also produce coconut fiber-based products, such as mats, ropes, and biodegradable packaging.

Case Studies: Successful Implementations

Case Study 1: Coconut Oil Processing Facility

Challenge: A company sought to establish a new facility for coconut oil production that emphasized efficiency and sustainability.

Solution: Lida Group designed and constructed a steel coconut factory that integrated multiple processing stages, from receiving to bottling.

Outcome: The facility was completed ahead of schedule, allowing the company to meet rising demand for coconut oil while minimizing its environmental impact.

Case Study 2: Coconut Water Bottling Plant

Challenge: A beverage company required a modern facility for bottling coconut water.

Solution: Lida Group developed a steel structure factory equipped with advanced bottling technology and quality control systems.

Outcome: The new plant improved production efficiency and product quality, leading to increased market share in the beverage industry.

Case Study 3: Coconut Fiber Processing Plant

Challenge: A company aimed to create a facility for processing coconut husks into fiber products.

Solution: Lida Group built a sustainable steel factory that included specialized machinery for fiber extraction and processing.

Outcome: The facility provided a valuable new revenue stream for the company and contributed to sustainable resource management.

The Future of Coconut Factories

Technological Innovations

The future of coconut factories will be shaped by ongoing technological advancements:

- Smart Factory Solutions: Integrating IoT devices can enhance monitoring and management of factory operations, improving operational efficiency.

- Automation: Advances in automation can streamline production processes, allowing for higher output and lower labor costs.

Sustainability Focus

As the coconut industry moves towards sustainability, steel structures will play a key role:

- Green Building Practices: The emphasis on environmentally friendly building materials and practices will drive further innovation in coconut factory design.

- Life Cycle Assessments: Conducting life cycle assessments will help manufacturers understand the full environmental impact of their products and processes.

Customization and Adaptability

The demand for customized and adaptable factory solutions will continue to grow:

- Tailored Designs: Steel coconut factories will increasingly offer customizable options that meet specific client needs and preferences.

- Flexible Configurations: The ability to easily modify or expand factory units will remain a key feature, ensuring they can adapt to changing project requirements.

Global Market Potential

The demand for coconut-based products is expected to grow globally:

- Emerging Markets: Developing countries will increasingly seek modern construction solutions to support their growing economies and infrastructure projects.

- Evolving Consumer Preferences: As consumers become more health-conscious, the demand for sustainably produced coconut products will rise.

Conclusion

Building innovative coconut factories using steel structures with Lida Group represents a significant advancement in the industry. By prioritizing efficient design, sustainable practices, and advanced technology, these factories not only enhance productivity but also contribute positively to the environment.

As the global demand for coconut-based products continues to rise, investing in steel coconut factories will empower companies to meet their operational needs while adhering to modern environmental standards. In a world increasingly focused on sustainability and adaptability, Lida Group’s steel structures stand at the forefront of industrial innovation, providing safe, functional, and eco-friendly spaces for coconut processing.

By embracing this approach, organizations can foster a more productive and efficient working environment, ultimately contributing to their long-term success and the well-being of the planet.

Post time: Apr-09-2025