In recent years, the global demand for poultry products has surged, driven by population growth and a rising preference for protein-rich diets. As poultry farming evolves to meet these demands, the need for innovative, efficient, and sustainable infrastructure becomes paramount. Lida Group, a leader in steel structure solutions, is at the forefront of this transformation, offering customized steel structures specifically designed for poultry farming. This article explores how Lida Group’s steel structure solutions are shaping the future of poultry farming, enhancing productivity, sustainability, and overall efficiency.

Understanding the Needs of Modern Poultry Farming

The Challenges Faced by Poultry Farmers

Poultry farming presents unique challenges that require tailored solutions. Some of the key challenges include:

- Biosecurity: Protecting flocks from diseases is critical for poultry farmers. This necessitates facilities that are easy to clean, maintain, and secure.

- Environmental Control: Poultry require specific environmental conditions for optimal growth, including temperature, humidity, and ventilation. Buildings must be designed to facilitate effective climate control.

- Space Efficiency: As the demand for poultry products increases, farmers need facilities that maximize space utilization while ensuring the welfare of the animals.

- Operational Efficiency: Streamlined workflows and efficient use of resources are essential for profitability in poultry farming.

The Role of Infrastructure in Poultry Farming

The infrastructure of a poultry farm directly influences its operational efficiency and productivity. Features such as adequate space, proper ventilation, and effective waste management systems are critical to maintaining healthy flocks and optimizing production. Traditional building materials often fall short in meeting these requirements, making steel structures an increasingly attractive option.

Why Choose Steel Structure Solutions?

1. Durability and Strength

Steel is renowned for its strength and durability. Structures built with steel can withstand harsh environmental conditions, including extreme weather, pests, and fire. This resilience is crucial for poultry farming, where the integrity of the building directly impacts the health and safety of the birds.

2. Customization

Lida Group specializes in providing customized steel structure solutions tailored to the specific needs of poultry farmers. From the design phase to construction, Lida Group works closely with clients to ensure that every aspect of the building aligns with their operational requirements. This level of customization allows for the incorporation of features such as:

- Ventilation Systems: Proper airflow is essential for maintaining a healthy environment for poultry. Customized designs can incorporate advanced ventilation systems that regulate temperature and humidity effectively.

- Biosecurity Measures: Steel structures can be designed with features that enhance biosecurity, such as controlled access points and smooth, easy-to-clean surfaces.

3. Speed of Construction

The prefabrication of steel components allows for rapid on-site assembly. This speed of construction is particularly beneficial for poultry farmers looking to expand or establish new facilities quickly. Lida Group’s efficient building processes ensure minimal disruption to ongoing operations, allowing farmers to start using their new facilities sooner.

4. Cost-Effectiveness

While the initial investment in steel structures may be higher than traditional materials, the long-term savings are substantial. Steel buildings require less maintenance, which translates to lower operational costs over time. Additionally, their energy-efficient designs can reduce utility bills, making them a financially savvy choice for poultry farmers.

5. Sustainability

Lida Group is committed to sustainability in its construction practices. Steel is a recyclable material, and many of the components used in Lida Group’s structures are sourced from recycled content. This sustainability focus not only benefits the environment but also aligns with the growing consumer demand for ethically produced poultry products.

Key Features of Lida Group’s Steel Structure Solutions for Poultry Farming

1. Climate Control Systems

Maintaining optimal conditions for poultry is essential for their growth and productivity. Lida Group’s steel structures can be equipped with advanced climate control systems, including:

- Insulation: High-quality insulation materials help regulate temperature fluctuations, ensuring a stable environment for poultry.

- Automated Ventilation: Smart ventilation systems can adjust airflow based on real-time conditions, maintaining ideal humidity and temperature levels.

2. Waste Management Solutions

Efficient waste management is critical in poultry farming to prevent disease and maintain a clean environment. Lida Group can integrate specialized waste management systems into their steel structures, including:

- Sloped Flooring: Designed to facilitate easy drainage and cleaning, sloped flooring systems help manage waste more effectively.

- Storage Solutions: Steel structures can be designed with dedicated areas for storing feed and waste, ensuring easy access and efficient management.

3. Biosecurity Features

To minimize the risk of disease outbreaks, biosecurity is a top priority in poultry farming. Lida Group’s steel structures can incorporate several biosecurity features, such as:

- Controlled Access Points: Designing entryways with controlled access helps limit the introduction of pathogens.

- Smooth Surfaces: Steel’s smooth surfaces are easier to clean and disinfect, reducing the risk of disease transmission.

4. Flexibility for Future Expansion

As poultry farming operations grow, the ability to expand facilities is crucial. Lida Group’s steel structures are designed with flexibility in mind, allowing for easy modifications and expansions without significant disruptions. This adaptability ensures that farmers can scale their operations in response to market demands.

Case Studies: Successful Implementations by Lida Group

1. Large-Scale Poultry Production Facility

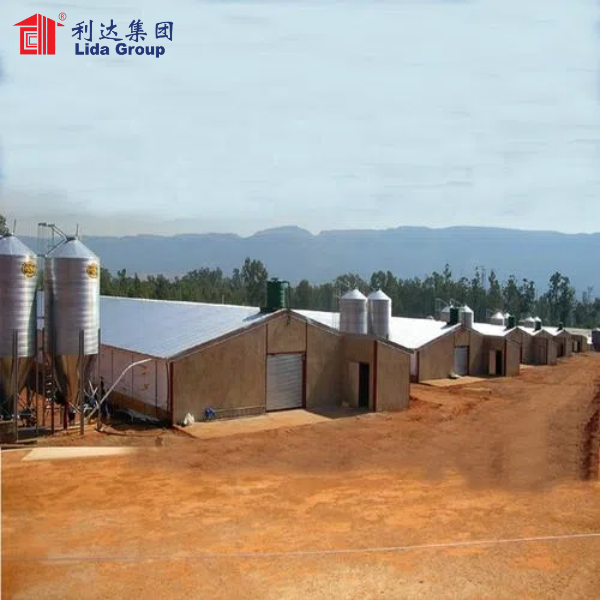

A major poultry producer approached Lida Group to construct a new facility to meet increasing demand. Lida Group designed a customized steel structure that included multiple climate-controlled sections for different poultry types. The facility featured advanced ventilation and waste management systems, resulting in improved productivity and reduced operational costs. The project was completed ahead of schedule, allowing the client to ramp up production quickly.

2. Free-Range Poultry Housing

An organic poultry farm sought a new housing solution for its free-range birds. Lida Group provided a steel structure that allowed for ample outdoor access while ensuring protection from predators and harsh weather. The design incorporated features such as insulated walls and automated ventilation systems, maintaining optimal living conditions for the birds. The client reported increased bird health and enhanced egg production following the construction of the new facility.

3. Poultry Processing Plant

A poultry processing company required a facility that combined production efficiency with biosecurity measures. Lida Group constructed a steel structure that included dedicated areas for processing, storage, and waste management. The design emphasized clean lines and smooth surfaces, facilitating easy cleaning and maintenance. The facility not only improved operational efficiency but also enhanced the company’s ability to meet regulatory standards.

The Future of Poultry Farming with Steel Structure Solutions

1. Increasing Demand for Sustainable Practices

As consumers become more aware of sustainability issues, poultry farmers are under pressure to adopt eco-friendly practices. Steel structures, with their recyclable materials and energy-efficient designs, align with this demand. Lida Group’s commitment to sustainability positions its steel solutions as a preferred choice for forward-thinking poultry farmers.

2. Technological Integration

The integration of technology in poultry farming is on the rise. Innovations such as IoT devices for monitoring environmental conditions and automated feeding systems are becoming standard in modern poultry facilities. Lida Group’s steel structures can easily accommodate these technologies, creating smart farming environments that enhance efficiency and productivity.

3. Resilience Against Climate Change

As climate change continues to impact agricultural practices, poultry farmers must adapt to changing conditions. Steel structures offer resilience against extreme weather events, ensuring that facilities remain operational regardless of external conditions. This durability is crucial for maintaining consistent production levels in the face of climate challenges.

4. Global Expansion of Poultry Markets

The global poultry market is expected to continue expanding, presenting opportunities for farmers to increase production. Lida Group’s steel structure solutions provide the scalability and flexibility needed to meet this growing demand. As farmers look to expand their operations, Lida Group’s innovative designs will play a crucial role in shaping the future of poultry farming.

Conclusion

Lida Group’s steel structure solutions are revolutionizing the poultry farming industry, offering customized, efficient, and sustainable infrastructure that meets the unique needs of modern farmers. With a focus on durability, flexibility, and advanced technology, Lida Group is well-positioned to support the growing demand for poultry products while promoting responsible farming practices.

As the poultry industry continues to evolve, Lida Group’s commitment to innovation and sustainability will ensure that its steel structure solutions remain at the forefront of this transformation. By investing in customized steel structures, poultry farmers can enhance their operational efficiency, improve animal welfare, and contribute to a more sustainable future.

In an era where the demand for poultry is rising, Lida Group stands ready to help farmers build the facilities of tomorrow, ensuring that they are equipped to meet the challenges of today and beyond. Embracing steel structure solutions is not just a choice for efficiency; it is a step toward a more sustainable and prosperous future in poultry farming.

Contact Us

Post time: Jan-15-2025