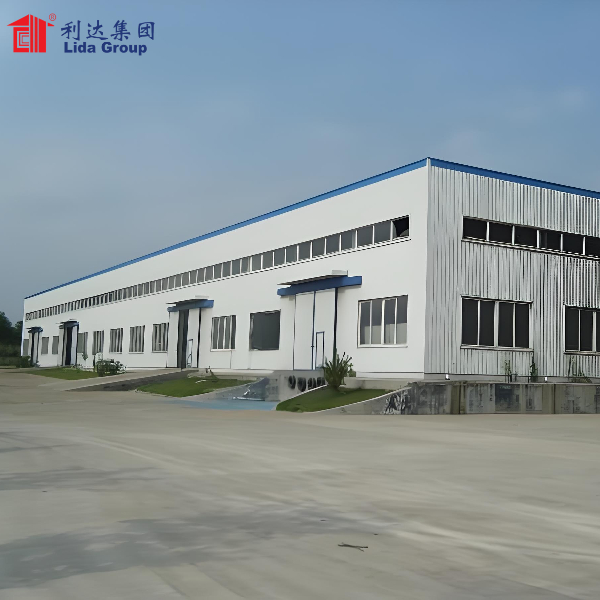

As industries around the world strive for efficiency, adaptability, and sustainability, the demand for innovative construction solutions has surged. Prefabricated workshops have emerged as a practical response to these needs, offering rapid deployment and customization tailored to various sectors. Lida Group, a leader in the prefabricated construction industry, has positioned itself at the forefront of this revolution with its cutting-edge prefab workshops. This article explores the benefits of Lida Group’s prefab workshops, their design innovations, and their impact across diverse industries.

Understanding Prefab Workshops

What Are Prefab Workshops?

Prefab workshops are structures that are manufactured off-site in a controlled environment and then transported to the site for assembly. This method allows for quicker construction times, reduced labor costs, and greater flexibility compared to traditional building methods. These workshops can be used for various purposes, including manufacturing, assembly, training, and storage.

Key Characteristics of Prefab Workshops

- Modularity: Prefab workshops are often designed in modular units, allowing for easy expansion and reconfiguration according to the needs of the business.

- Speed of Construction: The off-site manufacturing process significantly shortens the time from design to completion, enabling businesses to start operations sooner.

- Cost-Effectiveness: Prefabricated construction typically results in lower overall costs due to reduced material waste and labor expenses.

- Quality Control: Manufacturing in a controlled environment ensures that each component meets high-quality standards, reducing the likelihood of defects.

- Sustainability: Many prefab workshops are designed with eco-friendly materials and energy-efficient systems, aligning with modern sustainability goals.

Advantages of Lida Group’s Prefab Workshops

1. Enhanced Efficiency

Lida Group’s prefab workshops are designed to optimize operational efficiency.

- Streamlined Operations: The layout can be customized to facilitate smooth workflows, minimizing bottlenecks in production and maximizing productivity. This is particularly important in manufacturing environments where efficiency directly impacts output.

- Integration of Technology: Many prefab workshops can incorporate advanced technologies, such as automation and IoT systems, to enhance operational efficiency further. These technologies allow for real-time monitoring and management of workflows.

2. Customization and Flexibility

Lida Group’s prefab workshops offer unparalleled customization options.

- Tailored Designs: Clients can work with Lida Group to create workshop designs that meet their specific operational needs, whether for manufacturing, assembly, or research and development.

- Adaptability: As business needs evolve, Lida Group’s modular designs allow for easy reconfiguration or expansion of the workshop, ensuring that the facility can grow alongside the business.

3. Cost Savings

The financial advantages of Lida Group’s prefab workshops are significant.

- Reduced Construction Costs: The prefabrication process often leads to lower labor and material costs. This is especially beneficial for startups and small businesses that need to manage their budgets carefully.

- Lower Operating Costs: Many prefab workshops are designed to be energy-efficient, which can lead to significant savings on utility bills over time. Features like high-quality insulation and energy-efficient lighting contribute to these savings.

4. Quality Assurance

Lida Group emphasizes quality in its prefab workshops.

- Consistent Quality Standards: The controlled environment of the factory allows for rigorous quality control, ensuring that each component meets high standards before it is assembled on-site.

- Durability of Materials: Lida Group uses high-quality materials that are built to withstand the rigors of industrial use, ensuring long-lasting performance.

5. Sustainability

Lida Group is committed to promoting sustainable practices through its prefab workshops.

- Eco-Friendly Materials: The use of sustainable materials in construction helps minimize the environmental impact. This commitment resonates with clients who prioritize corporate social responsibility.

- Energy Efficiency: Many workshops incorporate energy-efficient systems and renewable energy options, allowing businesses to reduce their carbon footprint while also lowering operational costs.

Design Innovations in Lida Group’s Prefab Workshops

1. Modular Construction

Lida Group’s prefab workshops feature innovative modular designs.

- Flexible Layouts: The modular construction allows for easy customization of the workshop layout, enabling businesses to create spaces that are tailored to their operational needs.

- Scalability: As businesses grow, additional modules can be added without significant disruptions to existing operations, allowing for seamless expansion.

2. Advanced Materials

The use of advanced materials is a hallmark of Lida Group’s design philosophy.

- Lightweight and Durable: Prefab workshops are often constructed using lightweight yet durable materials, making them easier to transport and assemble while ensuring long-lasting performance.

- Weather-Resistant: The materials used in Lida Group’s workshops are designed to withstand various environmental conditions, ensuring that the structure remains intact and functional over time.

3. Integration of Technology

Lida Group incorporates cutting-edge technology into its prefab workshop designs.

- Smart Building Features: Many workshops are equipped with smart systems that allow for real-time monitoring of energy consumption, security, and environmental conditions. This technology enhances operational efficiency and safety.

- Data Analytics: Implementing data-driven solutions can optimize inventory management and operational workflows, reducing waste and improving overall efficiency.

4. Ergonomic Design

Lida Group emphasizes ergonomics in its workshop designs.

- Worker-Centric Layouts: Designs prioritize the comfort and safety of workers, incorporating ergonomic workstations and safety features to reduce the risk of injury.

- Natural Lighting: Many workshops are designed to maximize natural light, creating a pleasant working environment that can enhance employee morale and productivity.

Applications of Lida Group’s Prefab Workshops

Lida Group’s prefab workshops can be utilized across various industries, each with unique requirements.

1. Manufacturing

The manufacturing sector benefits significantly from Lida Group’s prefab workshops.

- Production Facilities: The workshops can be tailored to accommodate assembly lines, machinery, and storage areas, providing a comprehensive solution for manufacturing needs.

- Quality Control Areas: Dedicated spaces for quality assurance and testing can be integrated into the design, ensuring that products meet industry standards.

2. Research and Development

Prefab workshops serve as effective research and development facilities.

- Laboratories: The modular design allows for the creation of specialized laboratory spaces for testing and development, accommodating various scientific disciplines.

- Innovation Hubs: Companies can utilize prefab workshops as innovation hubs, fostering collaboration and creativity among teams.

3. Warehousing and Distribution

Lida Group’s workshops can also function as warehouses or distribution centers.

- Storage Solutions: The flexible design allows for efficient storage of goods, with customizable shelving and storage systems that maximize space utilization.

- Distribution Centers: Prefab workshops can be designed to facilitate the efficient movement of products from suppliers to customers, enhancing logistical operations.

4. Training Facilities

Training and educational purposes can be effectively served by prefab workshops.

- Training Centers: Workshops can be designed to accommodate training sessions, with customizable spaces for classrooms, equipment, and simulation labs.

- Corporate Training: Companies can use prefab workshops for corporate training sessions, ensuring that employees have access to the necessary resources in a conducive environment.

5. Agriculture

The agricultural sector can leverage Lida Group’s prefab workshops for various applications.

- Equipment Storage: Farmers can utilize workshops for storing machinery and equipment, ensuring that they are protected and easily accessible.

- Processing Facilities: Workshops can be designed for processing agricultural products, such as packaging and storage for fruits and vegetables.

The Implementation Process of Lida Group’s Prefab Workshops

1. Planning and Consultation

The implementation process begins with thorough planning and consultation.

- Needs Assessment: Understanding the specific requirements of the business is crucial for developing effective solutions. Lida Group collaborates closely with clients to identify their needs and objectives.

- Site Selection: Choosing the right location for the prefab workshop is essential for logistical efficiency and access to resources. Lida Group evaluates potential sites based on proximity to suppliers and transportation infrastructure.

2. Designing the Workshop

Selecting an appropriate design is essential for success.

- Custom Modular Solutions: Lida Group offers a variety of modular designs tailored to different needs and preferences, allowing clients to choose layouts that fit their vision.

- Compliance with Regulations: Ensuring that designs comply with local building codes and regulations is vital for a smooth implementation process.

3. Manufacturing and Prefabrication

Once designs are finalized, the manufacturing process begins.

- Production of Components: Prefab workshops are manufactured in a controlled environment, ensuring high quality and consistency throughout the construction process.

- Quality Control: Each component undergoes rigorous quality checks to meet industry standards and specifications, ensuring durability and reliability.

4. Site Preparation

While the units are being fabricated, site preparation takes place.

- Clearing and Grading: The site is cleared of obstacles and graded to ensure a level foundation for the workshops.

- Foundation Construction: A strong foundation may be laid, depending on the site conditions and intended use of the prefabricated units.

5. Assembly

The assembly phase is where the prefab workshops come together.

- Erection of Units: The modular units are assembled on-site, often using cranes or other lifting equipment for efficiency.

- Installation of Utilities: Electrical, plumbing, and HVAC systems are installed to ensure the workshops are fully operational and comfortable for employees.

6. Finishing Touches

After the main structure is complete, finishing touches are added.

- Interior Layout: Additional features such as storage areas, offices, and break rooms are constructed according to the design specifications.

- Exterior Finishing: The exterior of the units may be finished with weather-resistant materials to ensure durability and aesthetic appeal.

7. Final Inspection and Handover

Before the workshops are handed over to clients, a final inspection is conducted.

- Quality Assurance: Thorough checks ensure that all aspects of the prefab workshops meet quality standards and regulatory compliance.

- Client Walkthrough: A walkthrough with the client allows for any last-minute adjustments or modifications to be made.

Case Studies: Successful Implementations of Lida Group’s Prefab Workshops

Case Study 1: Manufacturing Facility

Challenge: A growing manufacturing company needed a new facility to expand production capacity quickly.

Solution: Lida Group designed and constructed a prefab manufacturing facility that optimized workflow and provided ample space for machinery and storage.

Outcome: The new facility enabled the company to increase production significantly, reducing lead times and improving overall efficiency.

Case Study 2: Agricultural Processing Workshop

Challenge: A cooperative sought a facility to process and package locally sourced agricultural products.

Solution: Lida Group provided a modular workshop designed for the specific needs of agricultural processing, including temperature control and storage solutions.

Outcome: The facility improved the cooperative’s efficiency and product quality, allowing them to expand their market reach.

Case Study 3: Research and Development Lab

Challenge: A tech company required a dedicated space for research and development to innovate new products.

Solution: Lida Group constructed a state-of-the-art R&D lab with customizable spaces for testing and collaboration.

Outcome: The new lab fostered innovation and accelerated product development, positioning the company as a leader in its field.

The Future of Prefab Workshops

Technological Innovations

The future of prefab workshops will be shaped by ongoing technological advancements.

- Smart Manufacturing: The integration of IoT and automation in manufacturing processes will enhance efficiency and reduce costs, leading to smarter workshop designs.

- Data-Driven Solutions: Utilizing data analytics to inform design and operational decisions can lead to more efficient and effective workshop operations.

Growing Demand

The demand for prefab workshops is expected to continue growing as industries seek faster, more flexible construction methods. Lida Group is well-positioned to meet this demand through its innovative solutions.

Focus on Sustainability

As environmental concerns drive the demand for sustainable practices, Lida Group’s commitment to eco-friendly designs and materials will resonate with clients seeking responsible construction options.

Global Market Potential

The demand for prefab workshops is anticipated to grow globally, particularly in regions experiencing rapid industrialization and urbanization. Lida Group aims to expand its reach, providing innovative solutions to meet the needs of diverse markets.

Conclusion

Lida Group’s prefab workshops represent a significant advancement in the construction landscape, offering efficient, flexible, and sustainable solutions for diverse industries. By prioritizing customization, quality, and innovation, Lida Group is addressing the evolving needs of businesses seeking to optimize their operations.

As the demand for prefab solutions continues to rise, Lida Group is well-equipped to lead the way in providing smart, adaptable, and eco-friendly workshop designs. The future of prefab workshops is bright, and Lida Group is committed to building a smarter, more efficient world for various industries.

Contact Us

Post time: Apr-24-2025