Lida Group Prefabricated Labour Camp for Construction Sites

Introduction

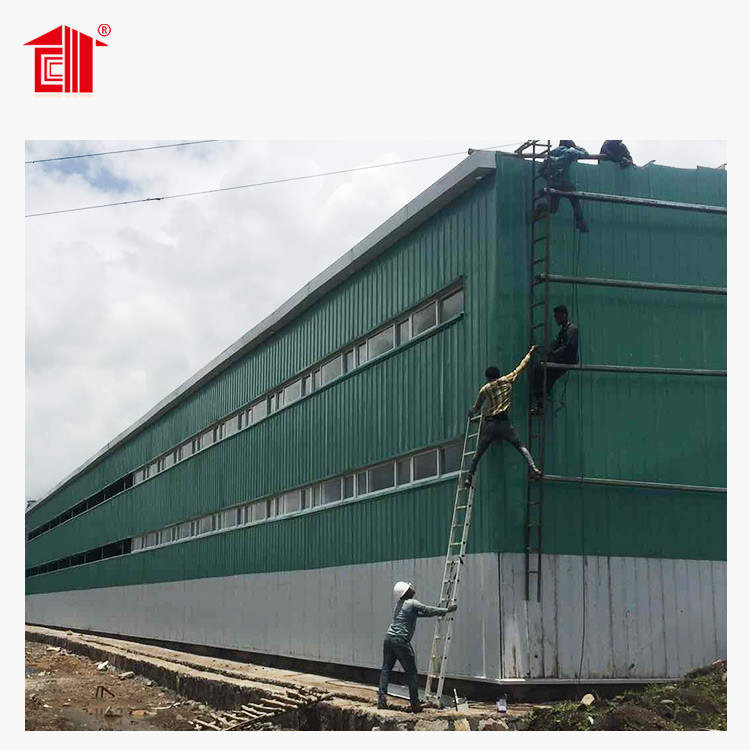

In the construction industry, providing suitable accommodation for workers on-site is crucial for the smooth execution of projects. Lida Group, a prominent provider of modular construction solutions, offers prefabricated labour camp solutions specifically designed to meet the unique demands of construction sites. This article explores the features and benefits of Lida Group’s prefabricated labour camps, focusing on their ability to provide comfortable living spaces, enhance productivity and safety, and offer a cost-effective solution for construction companies.

Prefabricated House is made of light steel as steel structure and sandwich panels for wall and roof. The sandwich panels can be polystyrene, polyurethane, rock wool and fiber glass sandwich panels for insulation.

The standard prefabricated house is made by 1.8m as one modular, and components connected by bolts. The house can be assembled and disassembled more than 6 times, and the service life is more than 20 years.

Lida Group understands the importance of creating an environment that promotes productivity and safety on construction sites. Their prefabricated labour camps are designed to optimize the living and working conditions, ensuring a conducive atmosphere for the workforce. The accommodations are equipped with amenities such as high-speed internet connectivity, dedicated workspaces, and communal areas for collaboration and interaction. Moreover, Lida Group emphasizes safety aspects by incorporating features such as fire-resistant materials, reliable electrical systems, and emergency exits. By providing suitable and well-equipped accommodations, Lida Group’s prefabricated labour camps contribute to a more productive and secure construction site.

Prefabricated House Main Material(for standard house):

1. Ground channel: C shape steel, C80x40x15x2.0

2. Column: Double C shape steel, 2C80x40x15x2.0 welded

3. Beam for second floor: Steel frame 2C80x40x15x2.0, L40x4 welded

4. Sub-beam for second floor: C shape steel, C80x40x15x2.0

5. Purlin for roof: Corner steel L40x4

6. Bracing for roof: Corner steel L40x4

7. Bracing for aisle and rain shelter: C shape steel, C80x40x15x2.0 welded

8. Bracing between the columns Round steelbolt φ 8

9. Step board Steel board t=3.0mm

10. Stair Steel stairs

11. Wall panel V950 EPS sandwich panel, 50mm thickness, steel plate: 0.3mm

12. Patition panel V950 EPS sandwich panel, 50mm thickness, steel plate: 0.3mm

13. Roof panel V950 EPS sandwich panel, 50mm thickness, steel plate: 0.3mm

14. Floor for second storey plywood 16mm thickness

15. Rain shelter One layer color steel plate 0.45mm thickness

16. Windows PVC sliding windows 0.93mx1.715m

17. Door Sandwich panel door 0.85mx2.1m

18. Entensive and commonbolt Different dimension

Prefabricated House Characteristics:

1. Environment protective, no garbage caused

2. Doors, windows and interior partitions can be flexibly fixed

3. Beautiful appearance, different colors for the wall and roof.

4. Cost saving and transportation convenient

5. Anti-rust and normally more than 15 years using life

6. Safe and stable, can stand 8 grade earthquake.

Technical Parameter of standard prefabricated house:

1. Wind resistance: Grade 11(wind speed≤ 111.5km/h)

2. Earthquake resistance: Grade 7

3. Live load capacity of roofing: 0.5kn/m2

4. External and internal wall heat transmission coefficient: 0.35Kcal/m2hc

5. Second Floor Load Capacity: 150 kg/m2

6. Live load of corridor is 2.0kn/ m2

Lida Group’s prefabricated labour camps offer a cost-effective and time-efficient solution for construction companies. The modular construction method allows for streamlined processes, reducing both construction time and costs. The use of prefabricated components minimizes wastage and material consumption, making it an environmentally friendly solution. Additionally, the modular nature of the accommodations enables easy scalability and relocation, allowing for future expansion or adaptation to changing project requirements. The cost-effectiveness and time efficiency of Lida Group’s prefabricated labour camps contribute to the overall profitability and operational success of construction projects.

To further illustrate the effectiveness and satisfaction of Lida Group’s prefabricated labour camps, let’s review a few case studies and testimonials:

a. Case Study: A large-scale infrastructure project utilized Lida Group’s prefabricated labour camp solution. The customized accommodations provided comfortable living spaces and dedicated work areas, resulting in enhanced productivity and job satisfaction. The cost-effectiveness and time efficiency of the solution allowed the construction company to meet project deadlines while maintaining high-quality living conditions for the workforce.

b. Testimonial 1: John Anderson, a project manager in the construction industry, commends Lida Group’s prefabricated labour camps for their flexibility and customization options. He highlights the ease of integrating specialized workspaces and project-specific requirements, which contributed to the smooth execution of the construction project. The comfortable living spaces and enhanced productivity of the workforce were key factors in the project’s success.

c. Testimonial 2: Sarah Williams, a construction site supervisor, praises Lida Group’s prefabricated labour camps for their cost-effectiveness and time efficiency. She highlights the streamlined construction process and the modular nature of the accommodations, which allowed for quick and easy deployment on-site. The provision of comfortable living spaces and amenities positively impacted the morale and productivity of the construction workers.