Introduction of Lida Integrated Labor Camp

Introduction of Lida Integrated Labor Camp

Lida Integrated Camps are widely used in General Contracting projects, Oil and gas field projects, Hydroelectric Projects, Military projects, mining sectors projects, and so on, which are intended for short- and long-term site mobilization.

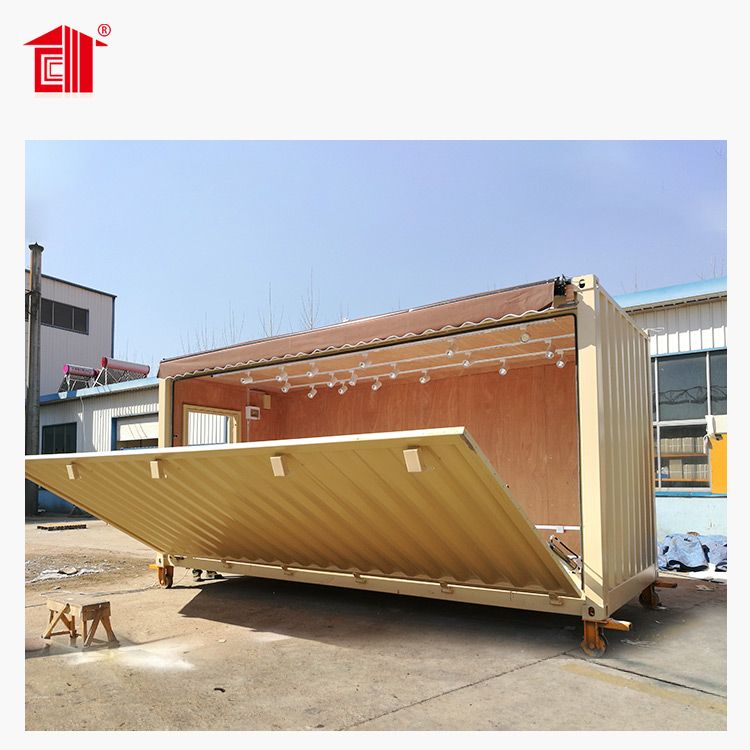

Lida Construction Site Labor Camp are designed to deliver the most appropriate and economical solution in terms of prefabricated house buildings, container house building or both of production system in line, which need to take the time, cost, site location, client requirements, and government regulations into consideration.

Comprehensive use of steel structure, prefab house and container house, Lida Group will offer you a one-stop service solution for the labor camp.

Lida Construction Site Labor Camp building is made of light steel as structure and sandwich panels for wall and roof. Insulation of sandwich panel can be polystyrene, polyurethane, rock wool and fiber glass, which is determined by the demand and environment requirements.

Lida Construction Site Labor Camp buildings can be assembled several times after one site construction finished, installed easily and cost effective.

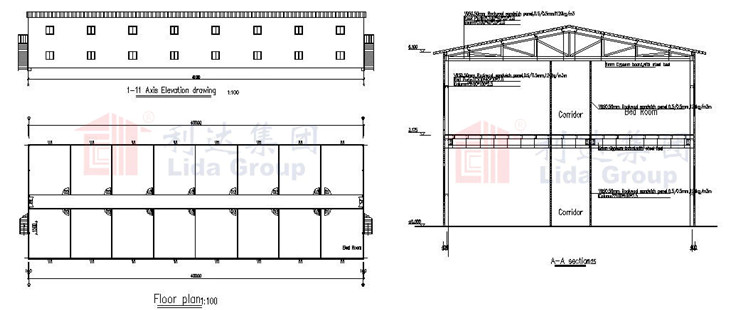

DESIGN DETAILS

Our expert team will advise you the solution based on your specific requirement for the camp buildings, location of the camp, staff quantity and the budget expectation.

ADVANTAGES

Advantages of Lida Integrated Camp

1. Size is customized, design according to requirements.

2. Service life is up to 15 years.

3.Cost effective, the average price is from USD 60/sqm to USD 120/sqm.

4.Fast construction. From production to installation, it only needs several months.

5.Green and Environmental, energy-saving, anti-fire, anti-earthquake, water proof.

6.Our 26 years’ experience in integrated camp building supply allows us to offer a complete one –stop integrated camp solution.

PRODUCT DETAILS

| Type | With or without steel chassis | Type one: without steel chassis, build on concrete strip foundation Type two: with steel chassis, the building will be put on concrete blocks |

| Storey | One storey or two storey or three storey are available | |

| Frame system | Steel column | Q235 Steel, 100*100*2.5 square tube, alkyd painting, twice primer paint & twice finish paint |

| Steel roof truss | C100*40*15*2.0, welding and galvanized | |

| Roof and wall purlin | C100*40*15*2.0, galvanized | |

| Cross bracing | Q235 Steel, L40*3 angle steel, alkyd painting, twice primer paint & twice finish paint | |

| Chemical bolt | M16, chemical bolt | |

| Ordinary bolt | 4.8S, galvanized | |

| Steel chassis or 1st floor system | Main beam | HN250*125*5.5*8, Q235 Steel, alkyd painting, twice primer paint & twice finish paint |

| Secondary beam | C100*40*15*2.0 galvanized | |

| Floor structure board | 18/20mm plywood and fiber cement board | |

| Flooring | PVC floor leather and ceramic tiles are available | |

| Wall and Roof system | Wall panel | Sandwich panel: Rock wool, Glass wool, EPS, PU are available Thickness: 50mm, 75mm, 100mm, 150mm, 200mm are available |

| Roof panel | Sandwich panel: Rock wool, Glass wool, EPS, PU are available Thickness: 50mm, 75mm, 100mm, 150mm, 200mm are available |

|

| Ceiling system | Dry room | 600*600*6mm gypsum board,with framework |

| Wet room | 600*600*5mm calcium silicate board, with framework | |

| Door and window system | Door | Fire resistant steel single/double door, emergency door with panic bar, aluminum glass door, MDF door are available |

| Window | PVC, Aluminum sliding window with single/double glazed glass, with mosquito screen, with louver are available | |

| Electric and Plumbing system | Electric units | Electric wire, conduit, socket, switch, light, distribution box |

| Sanitary units | Shower, closestool, basin, water pipe |