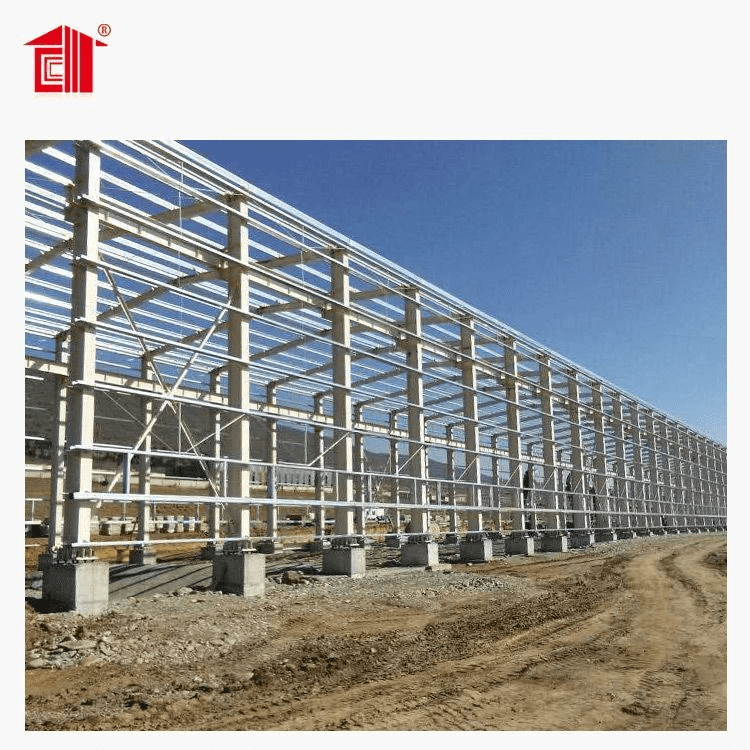

Industrial Structural Steel Construction: Heavy/Light Weight, Easy Assembly, Prefabricated/Prefab, Anti-Corrosion, Painted Galvanized Metal Frame Steel Structure

Heavyweight Strength for Industrial Demands

One of the foremost benefits of industrial structural steel construction is its heavyweight strength. Steel is renowned for its exceptional load-bearing capacity, making it ideal for industrial settings that require support for heavy machinery, equipment, and infrastructure. The high strength-to-weight ratio of steel allows for the creation of large, open spaces without the need for excessive columns and supports, maximizing usable floor areas. Industrial facilities such as manufacturing plants, warehouses, and distribution centers rely on the heavyweight strength of structural steel to ensure the safe storage and operation of their assets.

Easy Assembly for Rapid Construction

The ease of assembly is a key feature that sets industrial structural steel construction apart from other building methods. Steel components are typically fabricated off-site, allowing for precise manufacturing in controlled environments. This prefabrication process ensures high-quality construction and streamlines the assembly process on-site. The standardized steel components, such as beams, columns, and trusses, can be easily transported and quickly erected using bolted connections or welding techniques. The straightforward assembly of industrial structural steel constructions significantly reduces construction time, allowing for faster project completion and earlier occupancy of the facility.

| I. Description: | ||

| Lida Light steel structure building is a new type of building structure system, The building structure system is formed by the main steel framework through linking up H section, C section, Z section or U section steel components. Maintenance system uses different kinds of panels as wall and roof together with other components such as windows and doors. Lida light steel structure building is widely used in large factories, warehouses, workshops, bridges, stadiums and other buildings. |

||

| II. Characteristics: | ||

| 1. Wide span: single span or multiple spans, the max span clear distance is 36m, without middle columns. 2. Low cost: unit price range from USD35 to USD70/square meter FOB according to customer’s request. 3. Fast construction and easy in installation 4. Long term service life: more than 50 years. 5. Other characteristics: environmental protection, stable structure, earthquake resistance, water proofing, and energy saving. |

||

| III. Main parts of the steel structure building: | ||

| Light steel structural Main Steel Frame |

H section steel | Q345 steel 8mm/10mm Galvanized or Painting |

| Cross Support | Φ20, Steel Q235, Galvanized |

|

| Belt Bar | Φ89*3, Steel Q235 Galvanized |

|

| Small Brace | Φ12,Steel Q235 Galvanized |

|

| Ordinary Bolt | Galvanized Bolt | |

| roof | Purlin | C160*60*2,Steel Q235, Galvanized |

| Out-roof Panel | Sandwich Panel or corrugated steel sheet |

|

| FRP daylighting board | thickness 1.2mm | |

| Accessories | Glass glue, self-tapping screw etc. |

|

| Edge Cover | Made of color steel sheet thickness 0.5mm |

|

| Gutter | Made of steel sheet thickness 0.8mm |

|

| Rainspout | Φ110 PVC | |

| wall | Purlin | C160*60*2.5, Steel Q235, Galvanized |

| Wall | sandwich panel or corrugated steel sheet |

|

| Accessories | Glass glue, Self-tapping Screw etc. |

|

| Edge Cover | Made of color steel sheet thickness 0.4mm |

|

| Axial fan | Axial Fan | |

| Door | sliding door or Rolling shutter door | |

| Window | PVC or Aluminium alloy | |

| Crane | With or without crane in 5 tons to 20 tons | |

Painted Galvanized Metal Frame Steel Structure for Enhanced Performance

The integration of painted galvanized metal frame steel structures further enhances the performance and durability of industrial buildings. The galvanized steel frame provides exceptional corrosion resistance, protecting the structure from the damaging effects of moisture and environmental elements. The addition of a painted finish not only improves the visual appeal but also adds an extra layer of protection against corrosion. The painted galvanized metal frame steel structures are particularly beneficial in industrial environments where the buildings are subjected to high humidity, chemical exposure, or extreme weather conditions. These structures offer long-lasting performance, minimal maintenance, and a professional appearance.