Factory source Smart House Container - Prefab Modular House Flat Pack Container House for Hotel/Apartment/Office – Henglida

Factory source Smart House Container - Prefab Modular House Flat Pack Container House for Hotel/Apartment/Office – Henglida Detail:

Lida container houses include flat pack container house, foldable container house (folding container house), expandable container house, welding container house(customized container house)and modified shipping container house(converted shipping container house).

Lida steel container houses are designed and developed according to the standard size of shipping container regularly. It can also be customized as per clients’ special requirement. It can be used as office, meeting room, dormitory, shop, booth, toilet, storage, kitchen, shower room and so on. Lida Container house is widely used as the labor camp or army in general contracting projects, Oil and gas field projects, Hydroelectric Projects, Military projects, mining sectors projects, and so on, which are intended for short- and long-term site mobilization.

Lida container house has many advantages, like quick installation, easy move, highly turnover and long lifespan. Lida container house is of the advantages of heat proofing and waterproofing. Based on modular standard container house, container house can be grouped in horizontal and vertical. Flexible in layout and prefabricated to achieve different function purpose. Welcome to get quotes from Lida container house supplier.

Lida group has obtained ISO9001, CE (EN1090) certification, and has passed the factory audit of BV, SGS and TUV and other international authorities. Lida group is the designated supplier of the UN peacekeeping force camp, and the strategic cooperation supplier of large domestic and foreign contracting companies such as China Construction, China Railway, China Communications, etc. Up to now, Lida projects have been spread over 145 countries and regions.

Specification

1) 20ft: 6055*2435*2896mm

2) 40ft: 12192*2435*2896mm

3) Roof Type: Flat roof with organized internal water draining design

4) Storey: ≤3

Design parameter

1) Life span: up to 20years

2) Floor Live load: 2.0KN/m2

3) Roof Live load: 0.5KN/m2

4) Wind load: 0.6KN/m2

5) Earthquake-resistance: Grade 8, Fire-proof: Grade 4

Wall panel

1) Thickness: 75mm fiber glass sandwich panel, effective width: 1150mm

2) Exterior steel sheet (standard configuration): Corrugated 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-zinc thickness≥40g/m2

3) Insulation layer (standard configuration): 75mm Fiber glass, density≥50kg/m3, Fire-proof standard: grade A non-flambable

4) Interior steel sheet(standard configuration): Flat 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-Zinc thickness≥40g/m2

Roof system

1) Steel frame & accessories: Main roof frame: cold formed steel, thickness=2.5mm, galvanized. with 4pcs galvanized lifting corners. Roof purlin: C80*40*15*2.0, galvanized. Q235B steel

2) Roof panel: 0.4 or 0.5mm thickness Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum thickness≥70g/m2, 360° full connection

3) Insulation: 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3, Grade A fire-proof, nonflammable.

4) Ceiling board: V-170 type, 0.5mm Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum-zinc thickness≥40g/m2.

5) Industrial socket: Fixed in explosion-proof box at the top beam of the short side, with 1 main power plug for power connection between containers

Corner pillar

1) Cold rolled steel: 4pcs pillar with same dimension, thickness=3mm, steel grade Q235B.

2) Corner pillar and main frame are joined by hexagon socket head bolt, strength: grade 8.8. Filled with Fiberglass insulation

Floor System

1) Steel structure & accessories: Main floor frame: cold formed steel, thickness 3.5mm, galvanization; Floor purlin:C120*40*15*2.0, galvanized. Q235B steel. Standard container is Without forklift hole, it can be added according to customer’s requirement.

2) Insulation (optional): 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3. Flammability: gradeA, nonflammable.

3) Bottom covering (optional): 0.25mm color steel sheet, Zinc thickness≥70g/m2.

4) Floor board: 18mm thickness fiber cement board, Fire-proof: gradeB1. Density≥1.3g/cm3

5) Interior Flooring: 1.5mm thickness PVC leather, Blue marble color

Door & Window

1) Insulated light steel door: Entrance door is W850*H2030mm, Toilet door is W700*H2030mm.

2) PVC sliding window, double glass 5mm thickness, with mosquito screen and security bar. Standard window: W800*H1100mm(for 2.4meter’s container), W1130*H1100mm(for 3 meter’s container), Toilet window: W800*H500mm

Electric system

1) Rated power: 5.0 KW, suggestion external power source ≤3 in series.

2) Technical parameters: CEE industrial plug, socket voltage 220V- 250V, 2P32A, Fixed in explosion-proof box at the top beam of the short side, the electric cable in the roof is protected by PVC pipe with CE certification; Using IP44 standard power distribution box.

3) Electrical data: main power cable is 6 mm2, AC cable is 4 mm2, socket cable is 2.5 mm2, lighting & switch cable is 1.5 mm2. Five sockets, 1pc AC socket of 3holes 16A, 4pcs socket of 5holes 10A. 1pc single connection switch, 2pcs double tube LED light, 2*15W.

Painting

1) Primer painting: epoxy primer, Zinc color, thickness: 20 – 40 μm.

2) Finishing paint: Polyurethane finishing coat, white color, thickness: 40-50 μm. Total paint film thickness≥80μm. Galvanized components, galvanized layer thickness≥10μm (≥80g/m2)

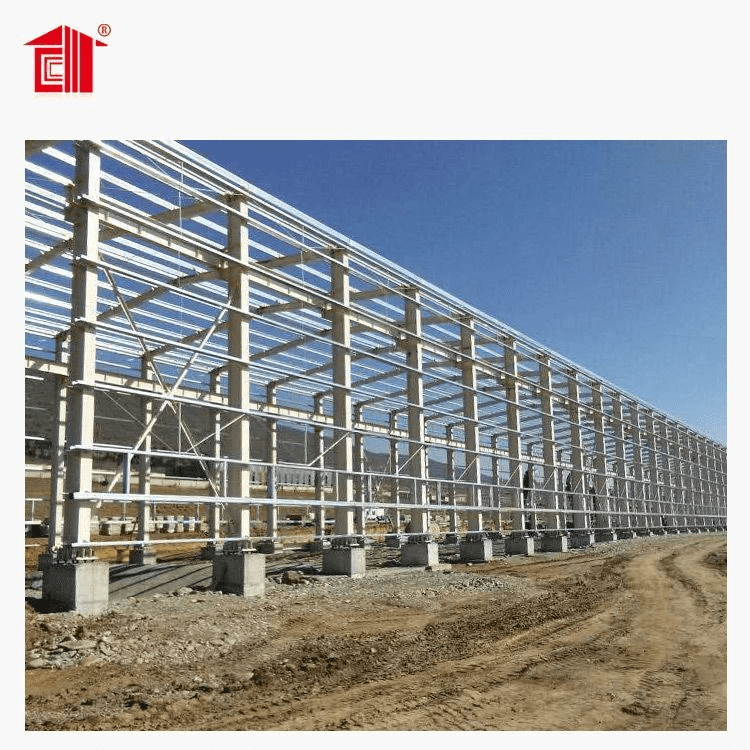

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Factory source Smart House Container - Prefab Modular House Flat Pack Container House for Hotel/Apartment/Office – Henglida , The product will supply to all over the world, such as: US, Honduras, Madrid, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.