Factory Cheap Hot Camp House - Defense & Military Camp House (Army Camp) – Henglida

Factory Cheap Hot Camp House - Defense & Military Camp House (Army Camp) – Henglida Detail:

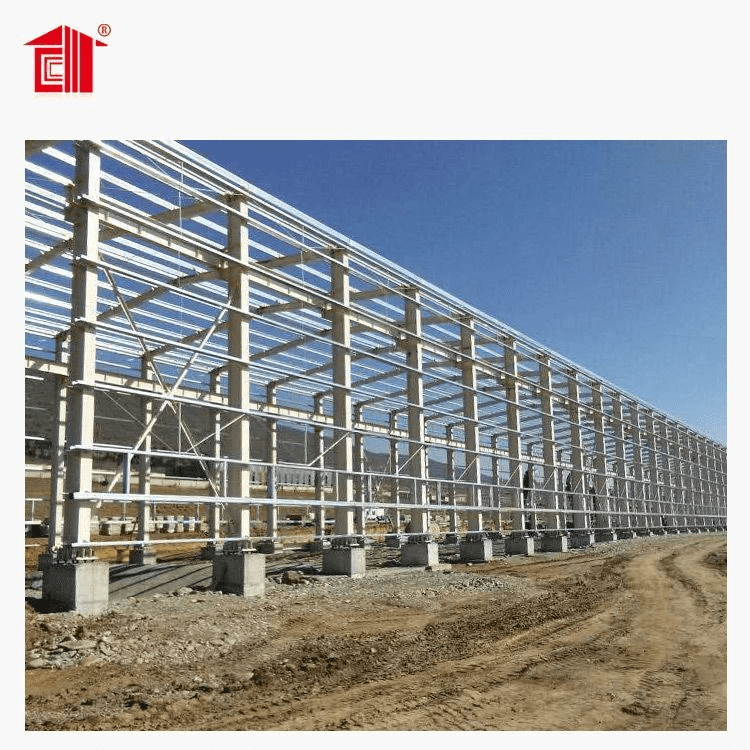

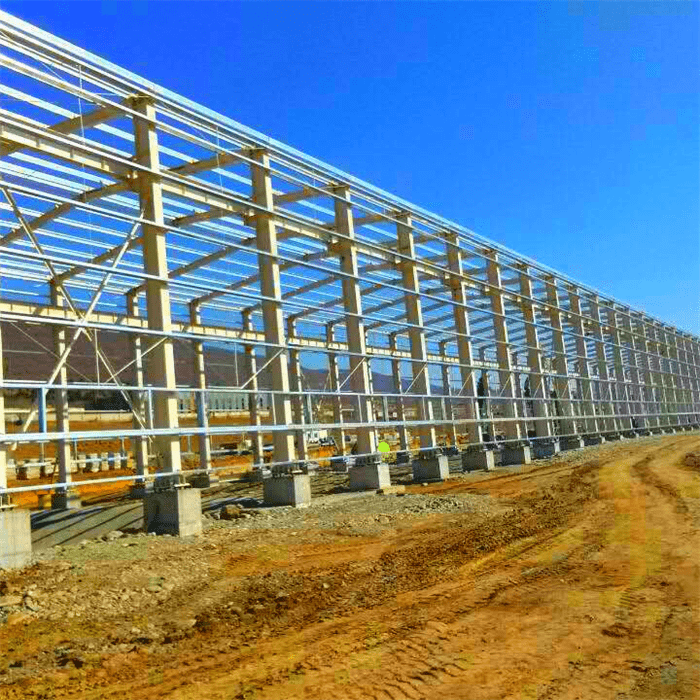

Lida Integrated Camp House are widely used for labor camp and military purpose in General Contracting projects, Oil and gas field projects, Hydroelectric Projects, Military projects, mining sectors projects, and so on, which are intended for short- and long-term site mobilization.

With the advantages of easy transportation, fast construction, flexible combination, the characters of modular military camp house (army camp house) are quite suitable for military use.

Lida Military camp housing can meet the Armed Services and their constituents. Today, Lida Group has provided lots of military camp house for UN and some countries.

Lida Military Camp House (Army Camp House) is designed to deliver the most appropriate and economical solution in terms of prefabricated house buildings, container house building or both of production system in line, which need to take the time, cost, site location, client requirements, and government regulations into consideration.

Comprehensive use of steel structure, prefab house and container house, Lida Group will offer you a one-stop service solution for the military camp (army camp).

Lida Military Camp House (Army Camp House) building is made of light steel as structure and sandwich panels for wall and roof. Insulation of sandwich panel can be polystyrene, polyurethane, rock wool and fiber glass, which is determined by the demand and environment requirements.

Lida Military Camp House (Army Camp House) buildings can be assembled several times after one site construction finished, installed easily and cost effective.

PRODUCT DETAILS

Our expert team will advise you the best turnkey solution based on your specific requirement for the camp buildings, location of the camp, staff quantity and the budget expectation.

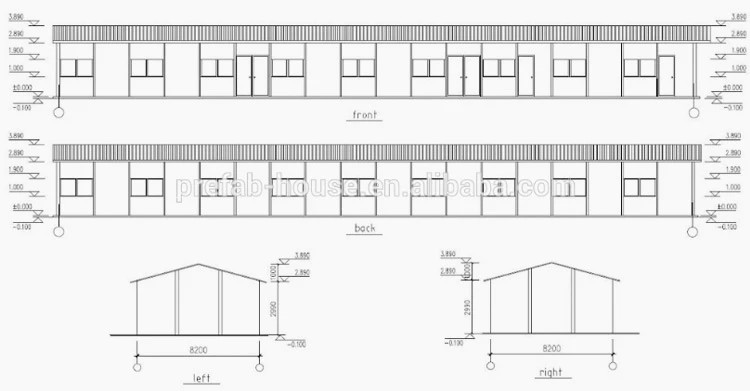

Integrated camp floor plan

Integrated camp floor plan

Integrated camp floor plan

LIDA MILITARY CAMP(ARMY CAMP) NORMALLY

INCLUDES THE FOLLOWING BUILDINGS AS FOLLOWING

Accommodation Building ,Kitchen and Dining Buildings, Clinic building(Medical center),Administration Office & Site Office, Laundry building, Camp warehouse, Recreation building, Prayer Room Market(Shop), Washing Room& Shower Room,etc.

ADVANTAGES

Advantages of Lida Integrated Camp

1. Size is customized, design according to requirements.

2. Service life is up to 15 years.

3. Cost effective, the average price is from USD 60/sqm to USD 120/sqm.

4. Fast construction. From production to installation, it only needs several months.

5. Green and Environmental, energy-saving, anti-fire, anti-earthquake, water proof.

6. Our 26 years’ experience in integrated camp building supply allows us to offer a complete one –stop integrated camp solution.

FORM INFORMATION

| Type | With or without steel chassis | Type one: without steel chassis, build on concrete strip foundation Type two: with steel chassis, the building will be put on concrete blocks |

| Storey | One storey or two storey or three storey are available | |

| Frame system | Steel column | Q235 Steel, 100*100*2.5 square tube, alkyd painting, twice primer paint & twice finish paint |

| Steel roof truss | C100*40*15*2.0, welding and galvanized | |

| Roof and wall purlin | C100*40*15*2.0, galvanized | |

| Cross bracing | Q235 Steel, L40*3 angle steel, alkyd painting, twice primer paint & twice finish paint | |

| Chemical bolt | M16, chemical bolt | |

| Ordinary bolt | 4.8S, galvanized | |

| Steel chassis or 1st floor system | Main beam | HN250*125*5.5*8, Q235 Steel, alkyd painting, twice primer paint & twice finish paint |

| Secondary beam | C100*40*15*2.0 galvanized | |

| Floor structure board | 18/20mm plywood and fiber cement board | |

| Flooring | PVC floor leather and ceramic tiles are available | |

| Wall and Roof system | Wall panel | Sandwich panel: Rock wool, Glass wool, EPS, PU are available Thickness: 50mm, 75mm, 100mm, 150mm, 200mm are available |

| Roof panel | Sandwich panel: Rock wool, Glass wool, EPS, PU are available Thickness: 50mm, 75mm, 100mm, 150mm, 200mm are available |

|

| Ceiling system | Dry room | 600*600*6mm gypsum board,with framework |

| Wet room | 600*600*5mm calcium silicate board, with framework | |

| Door and window system | Door | Fire resistant steel single/double door, emergency door with panic bar, aluminum glass door, MDF door are available |

| Window | PVC, Aluminum sliding window with single/double glazed glass, with mosquito screen, with louver are available | |

| Electric and Plumbing system | Electric units | Electric wire, conduit, socket, switch, light, distribution box |

| Sanitary units | Shower, closestool, basin, water pipe |

Component Specification of Lida Integrated Camp ( flat pack container house type)

Flat pack container house is made by steel frame structure, which adopts cold- form galvanized steel. Structure is consists of three modular parts: roofing frame, corner column and floor frame.

Each modular part is manufactured at the factory and assembled on construction site. With one single container house as basic unit, it can be combined horizontally or vertically in different form like building blocks.

Flat pack container house can be stacked in three storeys with flexible in space layout and multiple function, and can be used in different application fields.

TABLE PARAMETERS

We can offer turnkey operation for your site that includes planning&designing, material processing, installation and other construction material supply.

| Specification | 1) 20ft: 6055*2435*2896mm |

| 2) 40ft: 12192*2435*2896mm | |

| 3) Roof Type: Flat roof with organized internal water draining design | |

| 4) Storey: ≤3 | |

| Design parameter | 1) Life span: up to 20years |

| 2) Floor Live load: 2.0KN/m2 | |

| 3) Roof Live load: 0.5KN/m2 | |

| 4) Wind load: 0.6KN/m2 | |

| 5) Earthquake-resistance: Grade 8, Fire-proof: Grade 4 | |

| Wall panel | 1) Thickness: 75mm fiber glass sandwich panel, effective width: 1150mm |

| 2) Exterior steel sheet (standard configuration): Corrugated 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-zinc thickness≥40g/m2 | |

| 3) Insulation layer (standard configuration): 75mm Fiber glass, density≥50kg/m3, Fire-proof standard: grade A non-flambable | |

| 4) Interior steel sheet(standard configuration): Flat 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-Zinc thickness≥40g/m2 | |

| Roof system | 1) Steel frame & accessories: Main roof frame: cold formed steel, thickness=2.5mm, galvanized. with 4pcs galvanized lifting corners. Roof purlin: C80*40*15*2.0, galvanized. Q235B steel |

| 2) Roof panel: 0.4 or 0.5mm thickness Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum thickness≥70g/m2, 360° full connection | |

| 3) Insulation: 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3, Grade A fire-proof, nonflammable. | |

| 4) Ceiling board: V-170 type, 0.5mm Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum-zinc thickness≥40g/m2. | |

| 5) Industrial socket: Fixed in explosion-proof box at the top beam of the short side, with 1 main power plug for power connection between containers | |

| Corner pillar | 1) Cold rolled steel: 4pcs pillar with same dimension, thickness=3mm, steel grade Q235B. |

| 2) Corner pillar and main frame are joined by hexagon socket head bolt, strength: grade 8.8. Filled with Fiberglass insulation | |

| Floor System | 1) Steel structure & accessories: Main floor frame: cold formed steel, thickness 3.5mm, galvanization; Floor purlin:C120*40*15*2.0, galvanized. Q235B steel. Standard container is Without forklift hole, it can be added according to customer’s requirement. |

| 2) Insulation (optional): 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3. Flammability: grade A, nonflammable. | |

| 3) Bottom covering (optional): 0.25mm color steel sheet, Zinc thickness≥70g/m2. | |

| 4) Floor board: 18mm thickness fiber cement board, Fire-proof: grade B1. Density≥1.3g/cm3 | |

| 5) Interior Flooring: 1.5mm thickness PVC leather, Blue marble color | |

| Door & Window | 1) Insulated light steel door: Entrance door is W850*H2030mm, Toilet door is W700*H2030mm. |

| 2) PVC sliding window, double glass 5mm thickness, with mosquito screen and security bar. Standard window: W800*H1100mm(for 2.4meter’s container), W1130*H1100mm(for 3 meter’s container), Toilet window: W800*H500mm | |

| Electric system | 1) Rated power: 5.0 KW, suggestion external power source ≤3 in series. |

| 2) Technical parameters: CEE industrial plug, socket voltage 220V- 250V, 2P32A, Fixed in explosion-proof box at the top beam of the short side, the electric cable in the roof is protected by PVC pipe with CE certification; Using IP44 standard power distribution box. | |

| 3) Electrical data: main power cable is 6 mm2, AC cable is 4 mm2, socket cable is 2.5 mm2, lighting & switch cable is 1.5 mm2. Five sockets, 1pc AC socket of 3holes 16A, 4pcs socket of 5holes 10A. 1pc single connection switch, 2pcs double tube LED light, 2*15W. | |

| Painting | 1) Primer painting: epoxy primer, Zinc color, thickness: 20 – 40 μm. |

| 2) Finishing paint: Polyurethane finishing coat, white color, thickness: 40-50 μm. Total paint film thickness≥80μm. Galvanized components, galvanized layer thickness≥10μm (≥80g/m2) |

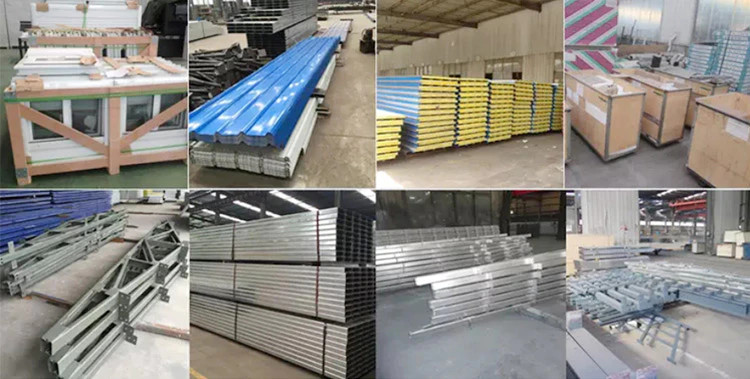

Packing and Loading of Lida Integrated Labor Camp

Packing and Loading of Lida Integrated Labor Camp

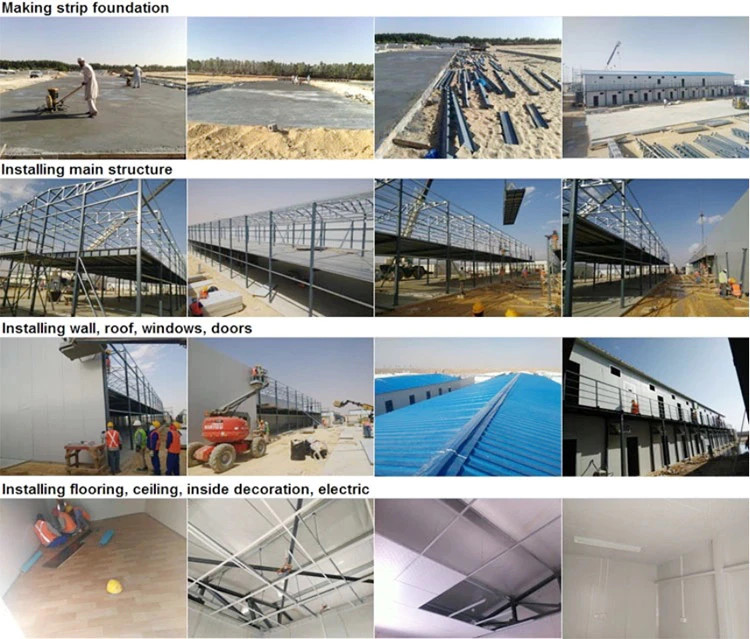

Installation of Lida Integrated Camp

Installation of Lida Integrated Camp

Finished Lida Integrated Labor Camp

Finished Lida Integrated Labor Camp

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Factory Cheap Hot Camp House - Defense & Military Camp House (Army Camp) – Henglida , The product will supply to all over the world, such as: Haiti, UAE, Los Angeles, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.