Crafting Quality: Steel Structure Workshops by Lida Group

Introduction

In the rapidly evolving landscape of modern manufacturing and craftsmanship, the demand for high-quality workshops has never been greater. These spaces not only serve as hubs of creativity and productivity but also need to be durable, flexible, and efficient. Lida Group, a leader in steel structure technology, has emerged as a key player in providing innovative steel structure workshops that meet the diverse needs of various industries. This article explores the features, benefits, and applications of Lida Group’s steel structure workshops, emphasizing their role in enhancing quality and efficiency in craftsmanship.

Understanding Steel Structure Workshops

What Are Steel Structure Workshops?

Steel structure workshops are industrial buildings constructed primarily from steel frameworks. This construction method offers numerous advantages, including strength, durability, and design flexibility. Steel structure workshops can be tailored to accommodate a wide range of activities, from manufacturing and assembly to artisanal crafts and educational workshops.

The Importance of Quality Workshops in Modern Industry

Quality workshops play a crucial role in various sectors:

- Enhanced Productivity: A well-designed workshop optimizes workflow, ensuring that processes run smoothly and efficiently.

- Safety and Compliance: Modern workshops must adhere to safety regulations, providing a secure environment for workers and minimizing risks.

- Flexibility and Adaptability: As industries evolve, workshops need to adapt to new technologies and methodologies, making flexibility a key consideration in their design.

Lida Group’s Commitment to Quality

A Legacy of Excellence

Founded with a vision of transforming construction practices, Lida Group has established itself as a leader in steel structure technology. With decades of experience, the company is committed to delivering high-quality solutions that meet the evolving needs of clients across various industries. This commitment is evident in every aspect of Lida Group’s steel structure workshops.

Advanced Design and Engineering

Lida Group employs state-of-the-art design and engineering techniques to craft workshops that are not only functional but also aesthetically pleasing. Key elements of their approach include:

- Customized Solutions: Lida Group works closely with clients to understand their specific needs, developing tailored workshops that optimize space and workflow.

- Use of Technology: The integration of advanced design software, such as Computer-Aided Design (CAD) and Building Information Modeling (BIM), allows for precise planning and visualization.

Quality Materials

Lida Group prioritizes the use of high-quality materials in its workshops. Steel, known for its strength and durability, forms the backbone of these structures. The company sources steel from reputable suppliers who adhere to strict quality standards, ensuring that every workshop is built to last.

Benefits of Lida Group’s Steel Structure Workshops

1. Structural Integrity and Durability

Lida Group’s steel structure workshops are designed to withstand harsh weather conditions and heavy loads. The inherent strength of steel ensures that these buildings remain safe and functional over time, providing a reliable workspace for various activities.

2. Cost-Effectiveness

The use of steel in workshop construction offers significant cost advantages:

- Lower Maintenance Costs: Steel structures require minimal maintenance compared to traditional materials like wood or concrete, reducing long-term expenses.

- Faster Construction: The prefabrication of steel components allows for quicker assembly on-site, reducing labor costs and project timelines.

3. Design Flexibility

One of the standout features of Lida Group’s steel structure workshops is their design flexibility. These workshops can be configured to meet a variety of needs, including:

- Open Floor Plans: The absence of internal columns allows for spacious, open layouts that can accommodate large machinery and equipment.

- Modular Designs: Workshops can be expanded or reconfigured as business needs change, ensuring long-term adaptability.

4. Enhanced Safety

Safety is paramount in any workshop environment. Lida Group’s steel structure workshops are designed with safety in mind:

- Robust Construction: The strength of steel provides a safe environment, reducing the risk of structural failures.

- Compliance with Safety Standards: Lida Group adheres to local and international safety regulations, ensuring that all workshops meet stringent safety requirements.

Applications of Lida Group’s Steel Structure Workshops

1. Manufacturing Facilities

Lida Group’s steel structure workshops are ideal for manufacturing operations across various industries. These workshops can accommodate a range of activities, from assembly lines to quality control.

- Customizable Layouts: Each manufacturing facility can be tailored to optimize workflow, ensuring that equipment and workstations are strategically placed for maximum efficiency.

2. Artisanal Workshops

For craftsmen and artisans, Lida Group offers workshops that provide the perfect environment for creativity and production. These spaces can be designed to accommodate activities such as woodworking, metalworking, and pottery.

- Dedicated Work Areas: Artisans can benefit from dedicated work zones, allowing for specialization and collaboration.

3. Educational Institutions

Educational institutions can utilize Lida Group’s steel structure workshops for vocational training and hands-on learning experiences. These workshops provide students with the opportunity to engage in practical skills development.

- Flexible Learning Spaces: Classrooms can be integrated into the workshop design, facilitating a seamless transition between theory and practice.

4. Maintenance and Repair Shops

Lida Group’s workshops are well-suited for maintenance and repair operations, providing ample space for vehicles and equipment.

- Efficient Service Areas: Workshops can be designed with specialized service bays, enhancing workflow and productivity.

The Construction Process

1. Initial Consultation and Planning

The construction of a Lida Group steel structure workshop begins with a comprehensive consultation to assess client needs. This phase includes:

- Site Evaluation: Assessing site conditions and constraints to inform design decisions.

- Design Collaboration: Working closely with clients to develop a customized workshop layout that meets their operational requirements.

2. Design Development

Once the initial consultation is complete, Lida Group’s design team creates detailed plans using advanced software. Key elements of this phase include:

- 3D Modeling: Visualizing the workshop layout and structure to ensure all specifications are met.

- Structural Analysis: Conducting simulations to assess the structural integrity of the design under various load conditions.

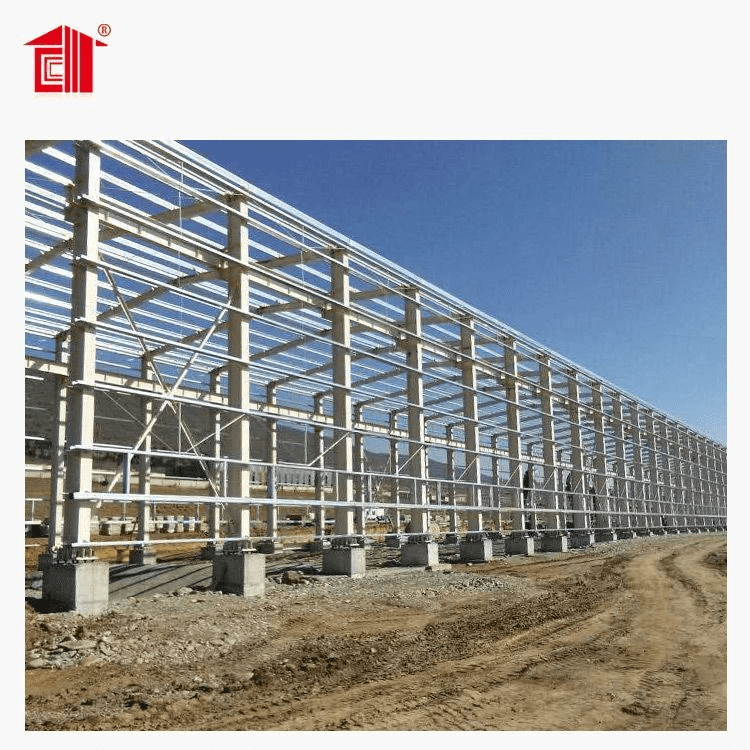

3. Prefabrication

After finalizing the design, Lida Group moves to the prefabrication stage:

- Precision Manufacturing: Steel components are fabricated off-site in a controlled environment, ensuring quality and consistency.

- Quality Assurance: Rigorous quality checks are conducted throughout the fabrication process to meet safety and performance standards.

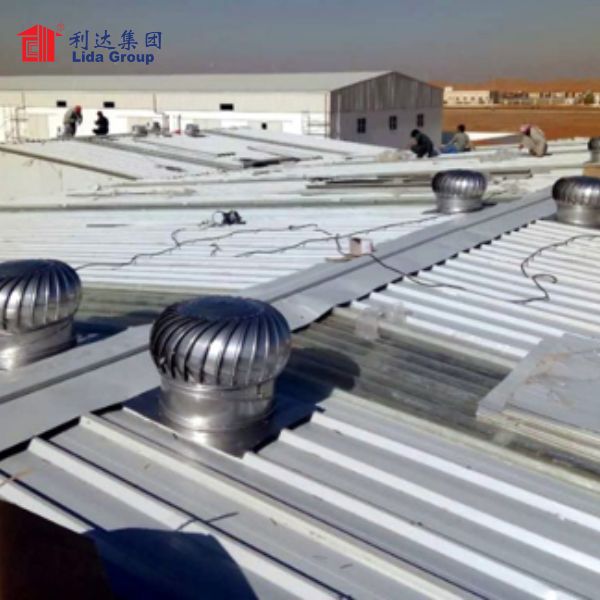

4. On-Site Assembly

The assembly phase involves transporting prefabricated components to the construction site for installation:

- Efficient Construction: With prefabricated components, assembly is quick and minimizes disruption to the surrounding area.

- Safety Protocols: Lida Group adheres to strict safety standards during construction, ensuring a safe working environment.

Sustainability in Steel Structure Workshops

1. Eco-Friendly Materials

Lida Group is committed to sustainability in its construction practices. The use of steel, which is 100% recyclable, minimizes the environmental impact of workshop construction.

2. Energy Efficiency

Lida Group incorporates energy-efficient systems into its workshop designs, such as:

- Insulation: High-quality insulation materials help regulate indoor temperatures, reducing the need for heating and cooling.

- Natural Lighting: Strategic placement of windows and skylights maximizes natural light, reducing energy consumption.

3. Waste Reduction

The prefabrication process minimizes on-site waste, as components are manufactured to precise specifications. This approach reduces material waste and promotes a more sustainable construction process.

Challenges and Solutions in Workshop Construction

1. Navigating Regulatory Compliance

Building codes and regulations can pose challenges for workshop construction. Lida Group addresses these challenges by:

- Thorough Research: Conducting extensive research to ensure all designs comply with local regulations.

- Engaging with Authorities: Collaborating with local authorities during the planning phase to streamline the approval process.

2. Supply Chain Management

Supply chain disruptions can impact project timelines. Lida Group mitigates these challenges by:

- Diverse Supplier Network: Building relationships with multiple suppliers to ensure material availability.

- Inventory Management: Utilizing advanced inventory management systems to track materials and anticipate shortages.

3. Weather Considerations

Weather conditions can affect construction schedules. Lida Group employs strategies such as:

- Flexible Scheduling: Adjusting construction timelines based on weather forecasts to minimize delays.

- Weather-Resistant Materials: Using materials designed to withstand harsh weather conditions, ensuring project durability.

The Future of Steel Structure Workshops

1. Increased Demand for Quality Workspaces

As industries continue to evolve, the demand for quality workspaces that enhance productivity and safety will grow. Lida Group is well-positioned to meet this demand with its innovative steel structure workshops.

2. Technological Advancements

The future of workshop design and construction will be shaped by advancements in technology:

- Smart Building Technologies: Integrating IoT devices for enhanced building management and maintenance.

- Automation: The use of automation in manufacturing processes will influence workshop layouts and equipment needs.

3. Global Expansion

Lida Group aims to expand its reach internationally, providing steel structure workshop solutions to diverse markets. This expansion will involve:

- Collaborations: Partnering with local contractors and governments to promote steel structure workshops in developing regions.

- Adapting Designs: Customizing designs to meet the unique needs and preferences of different cultures and climates.

Conclusion

Lida Group’s steel structure workshops represent a significant advancement in the quest for quality and efficiency in craftsmanship. By combining innovative design, advanced technology, and a commitment to sustainability, Lida Group is redefining how industries approach workspace construction.

As the demand for modern, efficient workshops continues to rise, Lida Group is poised to lead the way in delivering high-quality steel structure solutions that meet the evolving needs of businesses and craftsmen worldwide. Through a focus on safety, flexibility, and sustainability, Lida Group is shaping the future of workshops and enhancing the quality of work in various industries, ensuring that craftsmanship thrives in a supportive and well-designed environment.