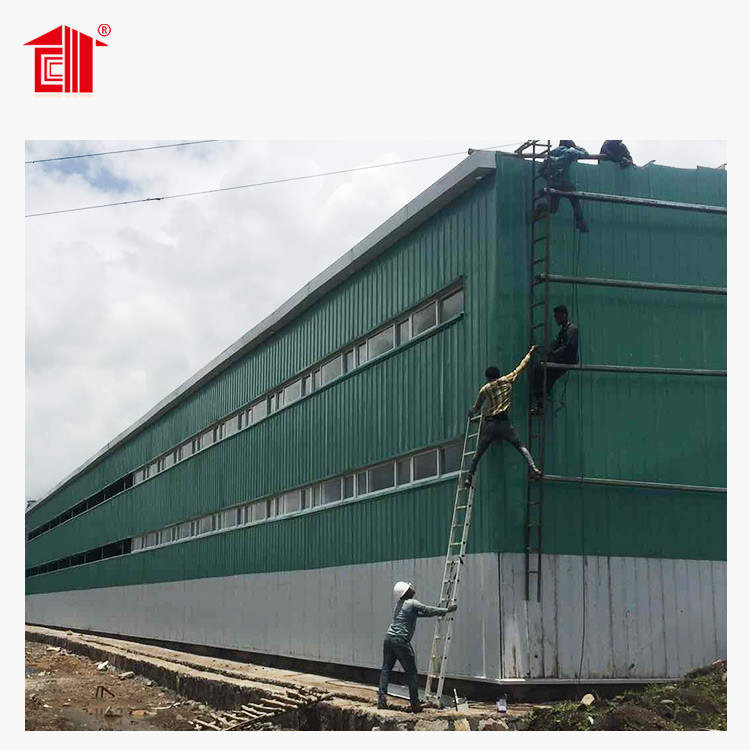

2 Floor Steel Structure Site Accommodation Prefabricated K Model Prefab House

Introduction

In the face of rapid urbanization and the growing need for efficient housing solutions, the construction industry is increasingly turning to prefabricated structures. Among these innovations, the two-floor steel structure site accommodation, particularly the K Model prefab house, has gained significant attention. This article delves into the design, benefits, applications, and future prospects of K Model prefab houses, highlighting their role in providing sustainable and effective housing solutions for various industries.

Understanding Prefabricated Houses

What Are Prefabricated Houses?

Prefabricated houses are structures built using pre-manufactured components that are assembled on-site. This construction method contrasts with traditional building approaches, which often take longer and involve more labor and material waste. Prefabricated houses can be made from various materials, including wood, concrete, and steel, and can be designed for different purposes, from residential homes to commercial buildings.

The Rise of Steel Structure Prefab Houses

Steel structure prefab houses have become increasingly popular due to their durability, strength, and flexibility. Steel is a robust material that can withstand harsh weather conditions, making it ideal for various applications, including site accommodation, temporary housing, and permanent residences. The K Model prefab house, specifically, exemplifies modern design and functionality.

The K Model Prefab House

Design Features

The K Model prefab house is characterized by its innovative design and efficient use of space. Key features include:

- Two-Floor Structure: This design maximizes vertical space, allowing for more living and working areas within a compact footprint.

- Modular Construction: The K Model is built using modular components, enabling quick assembly and disassembly.

- Steel Frame: The use of a steel frame provides structural integrity and longevity, ensuring the house can withstand various environmental conditions.

- Insulated Panels: High-quality insulated panels contribute to energy efficiency, maintaining comfortable indoor temperatures.

Customization Options

One of the standout features of the K Model prefab house is its adaptability. Clients can customize various aspects to meet their specific needs:

- Room Configurations: Different layouts can accommodate various numbers of occupants, from single individuals to larger groups.

- Interior Finishes: Homeowners can select finishes that reflect their style, including flooring, cabinetry, and paint colors.

- Exterior Design: The exterior can be tailored with different cladding materials and colors to blend with the surrounding environment.

Benefits of K Model Prefab Houses

Cost-Effectiveness

The K Model prefab house offers significant cost savings compared to traditional construction methods:

- Reduced Labor Costs: Prefabrication minimizes on-site labor requirements, lowering overall construction costs.

- Shorter Build Time: Quick assembly means that the house can be ready for use in a fraction of the time it takes to build a conventional home.

- Lower Material Waste: Efficient manufacturing processes reduce waste, contributing to cost savings.

Durability and Safety

Steel structure prefab houses are known for their durability and safety:

- Weather Resistance: Steel can withstand extreme weather conditions, including heavy winds, rain, and snow.

- Fire Resistance: Steel structures are non-combustible, offering enhanced fire safety compared to traditional wooden buildings.

- Seismic Resilience: Steel’s strength makes it an excellent choice for areas prone to earthquakes, providing peace of mind for occupants.

Energy Efficiency

K Model prefab houses are designed with energy efficiency in mind:

- Insulation: High-quality insulation materials help maintain comfortable indoor temperatures, reducing heating and cooling costs.

- Natural Lighting: Thoughtful window placement maximizes natural light, reducing the need for artificial lighting during the day.

- Sustainable Materials: Many components are made from recycled or sustainable materials, contributing to a lower environmental impact.

Applications of K Model Prefab Houses

Site Accommodation

The primary application of K Model prefab houses is in site accommodation for various industries:

- Construction Sites: Workers need comfortable living quarters, and K Model houses provide a practical solution that can be set up quickly.

- Mining Operations: Remote mining sites often require temporary housing for workers; K Model houses offer a durable and livable option.

- Disaster Relief: In the aftermath of natural disasters, K Model prefab houses can be rapidly deployed to provide emergency housing.

Temporary and Permanent Housing

Beyond site accommodation, K Model prefab houses can serve as both temporary and permanent housing solutions:

- Student Housing: Universities can utilize K Model houses to provide affordable housing for students, especially in high-demand areas.

- Affordable Housing Initiatives: Governments and organizations can implement K Model houses in affordable housing programs to meet the needs of low-income families.

- Vacation Homes: K Model prefab houses can be designed as vacation homes, offering a quick and cost-effective solution for recreational properties.

Offices and Commercial Spaces

The K Model’s versatility extends beyond residential use:

- Portable Offices: Businesses can set up portable offices using K Model prefab houses, ideal for project sites or temporary locations.

- Retail Spaces: The modular design allows for the creation of retail units that can be easily relocated as needed.

The Manufacturing Process

Production of K Model Prefab Houses

The manufacturing process for K Model prefab houses involves several key steps:

- Design and Engineering: Architects and engineers work together to create efficient and functional designs tailored to client needs.

- Material Sourcing: Quality materials, particularly steel and insulation, are sourced from reliable suppliers.

- Fabrication: Components are fabricated in a controlled environment, ensuring high quality and precision.

- Flat Packing: Once completed, the components are flat-packed for transportation, optimizing shipping costs.

- On-Site Assembly: The components are delivered to the site and assembled quickly, often within days.

Quality Control

Quality control is essential throughout the manufacturing process:

- Inspection: Each component undergoes thorough inspection to ensure it meets safety and quality standards.

- Testing: Structural integrity and safety features are tested to guarantee reliability.

- Certification: Compliance with national and international building codes is verified through certification processes.

Sustainability and Environmental Impact

Eco-Friendly Construction Practices

K Model prefab houses align with sustainable building practices:

- Recycling Materials: Steel is a highly recyclable material, reducing the environmental impact of construction.

- Energy Efficiency: The energy-efficient design minimizes resource consumption and lowers carbon emissions.

- Sustainable Sourcing: Manufacturers increasingly prioritize sourcing materials from sustainable suppliers.

Long-Term Benefits

Investing in sustainable construction practices not only benefits the environment but also offers long-term advantages:

- Lower Operating Costs: Energy-efficient homes result in reduced utility bills, providing financial relief to occupants.

- Increased Property Value: Sustainable features can enhance property value, making these homes attractive investments.

- Resilience to Climate Change: Durable and energy-efficient designs contribute to long-term resilience against climate-related challenges.

Challenges and Considerations

Regulatory Hurdles

Navigating local building codes and regulations can present challenges for prefabricated housing:

- Zoning Laws: Different regions have varying zoning laws that may affect where prefab houses can be placed.

- Building Codes: Compliance with safety and structural codes is essential, requiring thorough understanding and planning.

Public Perception

Despite their advantages, prefab houses may face skepticism:

- Stigma: Some individuals may associate prefab houses with lower quality or temporary housing.

- Education: It is crucial to educate the public about the benefits and quality of K Model prefab houses to overcome misconceptions.

Market Competition

As the demand for prefabricated housing grows, competition among manufacturers intensifies:

- Quality Differentiation: Companies must focus on quality and innovation to stand out in a crowded market.

- Customer Service: Excellent customer service and support can help build trust and loyalty among clients.

Future Trends

Growing Demand for Affordable Housing

The ongoing housing crisis in many regions highlights the need for affordable housing solutions. K Model prefab houses are well-suited to meet this demand, providing cost-effective options for individuals and families.

Technological Advancements

Technological innovations will continue to shape the future of prefabricated housing:

- Smart Home Integration: As technology advances, prefab houses can incorporate smart home features, enhancing convenience and energy efficiency.

- 3D Printing: The use of 3D printing in construction may further streamline the manufacturing process and reduce costs.

Increased Focus on Sustainability

As awareness of environmental issues rises, the construction industry will increasingly adopt sustainable practices. K Model prefab houses align with this trend, providing eco-friendly solutions for modern living.

Conclusion

The K Model two-floor steel structure site accommodation prefab house represents a significant advancement in construction technology. Its combination of cost-effectiveness, durability, and sustainability makes it an ideal solution for various applications, from site accommodation to permanent housing.

As the demand for innovative housing solutions continues to grow, prefabricated houses like the K Model will play a crucial role in meeting the needs of individuals and communities. By embracing this modern approach to construction, we can create efficient, sustainable, and comfortable living and working environments for the future.