The Advantages of Custom Steel Structure Poultry Farming Buildings by Lida Group

As the global demand for poultry products continues to rise, farmers are increasingly looking for innovative solutions to enhance productivity, ensure animal welfare, and reduce operational costs. One of the most effective strategies to achieve these goals is the adoption of custom steel structure buildings specifically designed for poultry farming. Lida Group, a leader in providing tailored steel solutions, offers a range of advantages that these buildings bring to poultry operations. This article explores the numerous benefits of custom steel structure poultry farming buildings and how Lida Group is transforming the industry.

Understanding Custom Steel Structure Buildings

What Are Custom Steel Structure Buildings?

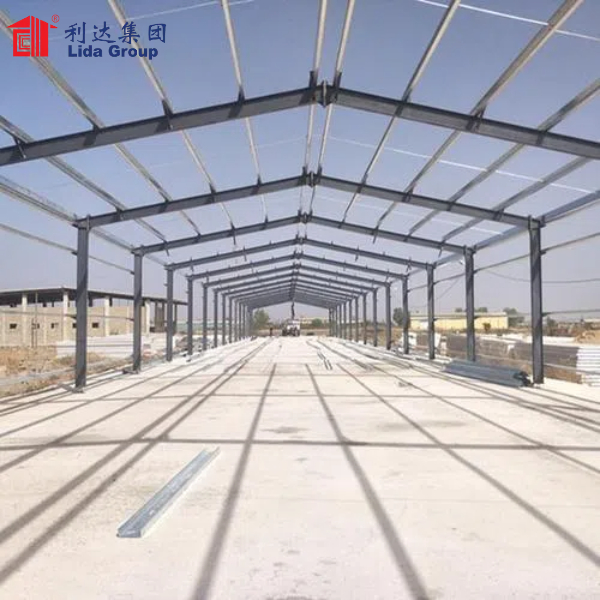

Custom steel structure buildings are specialized constructions made primarily from steel, designed to meet the unique needs of poultry farming operations. These structures are engineered to provide optimal conditions for raising poultry, including adequate space, ventilation, and biosecurity measures.

Key Features of Custom Steel Structures

- Tailored Design: Custom steel buildings can be designed to fit specific dimensions, layouts, and operational requirements of a poultry farm, ensuring maximum efficiency.

- Durability: Steel is known for its strength and resistance to various environmental factors, making it a long-lasting choice for poultry housing.

- Modular Construction: Many steel structures are built using modular components, allowing for easy expansion or reconfiguration as the farm grows.

- Sustainability: Steel is a recyclable material, and using it in construction supports environmentally friendly practices.

The Importance of Poultry Farming Infrastructure

1. Meeting Growing Consumer Demand

The global poultry market is expanding rapidly. With increasing populations and changing dietary preferences, the demand for poultry products is projected to rise significantly. To meet this growing demand, poultry farmers need efficient and scalable infrastructure.

2. Enhancing Biosecurity

Biosecurity is a critical concern in poultry farming. Effective biosecurity measures are vital to prevent the spread of diseases that can devastate flocks. Custom steel structure buildings allow for the implementation of advanced biosecurity protocols, reducing the risk of contamination.

3. Improving Animal Welfare

Animal welfare is essential for both ethical considerations and productivity. Custom steel structures can be designed to provide optimal living conditions for poultry, allowing farmers to maintain high welfare standards.

Advantages of Custom Steel Structure Poultry Farming Buildings

1. Flexibility and Customization

One of the primary advantages of custom steel structure buildings is their flexibility. Lida Group offers tailored designs that cater to the specific needs of poultry farms:

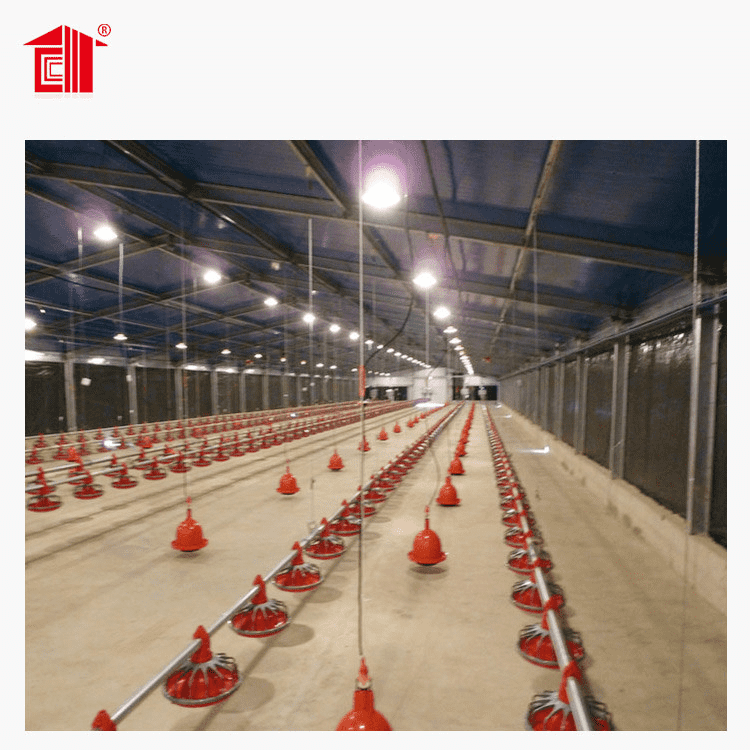

- Size and Layout: Custom buildings can be designed to accommodate different flock sizes, ensuring that birds have enough space to move freely and thrive.

- Functional Areas: Steel structures can be divided into various functional areas, including feeding zones, nesting areas, and processing facilities, optimizing workflow and efficiency.

2. Enhanced Biosecurity

Custom steel structures can be designed with biosecurity in mind:

- Controlled Access Points: Buildings can include designated entry and exit points to control the movement of people and equipment, reducing the risk of disease transmission.

- Seamless Surfaces: The smooth surfaces of steel make cleaning easier, allowing for effective sanitation practices that minimize pathogen spread.

3. Improved Climate Control

Poultry thrive in specific environmental conditions. Custom steel buildings can be designed to provide effective climate control:

- Ventilation Systems: Advanced ventilation systems can be integrated to maintain optimal air quality and temperature, ensuring the health and comfort of the birds.

- Insulation Options: Custom designs allow for the incorporation of insulation materials that help regulate temperature, reducing energy costs while maintaining a stable environment.

4. Cost-Effectiveness

Investing in custom steel structure buildings can lead to significant cost savings:

- Lower Construction Costs: The efficiency of prefabrication and modular construction can reduce labor and material costs, making it an affordable option for farmers.

- Reduced Maintenance Costs: Steel’s durability means less frequent repairs and lower long-term maintenance expenses, allowing farmers to allocate resources more effectively.

5. Scalability and Future Growth

As poultry operations expand, the need for scalable solutions becomes critical. Custom steel structures offer several advantages in this area:

- Easily Expandable: Custom designs can incorporate plans for future expansion, allowing farmers to increase their capacity without significant disruption.

- Modular Systems: The modular nature of steel structures allows for easy reconfiguration, enabling farmers to adapt to changing market demands.

6. Sustainability and Environmental Responsibility

Sustainability is becoming increasingly important in agriculture. Custom steel structures align with environmentally friendly practices:

- Recyclable Materials: Steel is a recyclable material, contributing to a circular economy and reducing waste.

- Energy Efficiency: Custom buildings can be designed with energy-efficient systems and materials, further minimizing their environmental impact.

7. Enhanced Worker Safety and Comfort

The design of custom steel structures can also prioritize worker safety and comfort:

- Ergonomic Design: Custom layouts can include features that enhance worker ergonomics, promoting safety and productivity.

- Natural Light: Incorporating windows and skylights can improve natural lighting, creating a more pleasant working environment for employees.

Lida Group’s Commitment to Custom Solutions

1. Comprehensive Consultation Process

Lida Group understands that every poultry operation has unique requirements. Their process begins with a comprehensive consultation to assess the specific needs of each farm:

- Needs Assessment: This involves understanding the size of the flock, production goals, and any specific challenges the farm faces.

- Tailored Design Proposals: Based on the assessment, Lida Group provides bespoke design proposals that optimize space and functionality.

2. High-Quality Manufacturing Standards

Quality is a cornerstone of Lida Group’s operations:

- Advanced Prefabrication Techniques: Components are manufactured in a controlled environment, ensuring high standards of quality and consistency.

- Rigorous Testing: Each component undergoes rigorous testing to ensure it meets high standards of durability and performance.

3. Efficient Construction Process

Lida Group’s construction process is designed to minimize downtime for poultry farmers:

- Rapid Assembly: Prefabricated components allow for quick on-site assembly, enabling farmers to start operations sooner.

- Skilled Workforce: A team of experienced professionals oversees the construction process, ensuring that each building is completed to the highest standards.

4. Ongoing Support and Maintenance

Lida Group is committed to providing ongoing support even after the construction is complete:

- Maintenance Services: Offering maintenance services to ensure that the buildings remain in optimal condition.

- Customer Support: Providing customers with the necessary resources and support to address any issues that may arise post-construction.

Case Studies: Successful Implementations by Lida Group

Case Study 1: Large-Scale Poultry Producer

Lida Group was approached by a large-scale poultry producer looking to improve their existing facilities. The project involved:

- Custom Design: A steel structure was designed to accommodate additional flock sizes while ensuring optimal ventilation and biosecurity measures.

- Timely Deployment: The prefabricated components were assembled on-site within weeks, allowing the farm to increase its production capacity quickly.

- Positive Outcomes: The new facility improved overall flock health and productivity, leading to increased profits for the farm.

Case Study 2: Organic Poultry Farming Operation

In another project, Lida Group collaborated with an organic poultry producer to create a sustainable housing solution:

- Sustainable Design: The steel structure incorporated solar panels and rainwater harvesting systems, reducing the farm’s environmental impact.

- Enhanced Animal Welfare: The spacious design allowed for natural light and airflow, promoting the health and well-being of the birds.

- Market Demand: The innovative building design helped the farm meet rising consumer demand for organic poultry products.

The Future of Custom Steel Structure Poultry Farming Buildings

1. Increasing Demand for Poultry Products

With the global population growing and shifting dietary habits, the demand for poultry products is expected to rise. Custom steel structure buildings will play a crucial role in meeting this demand efficiently and sustainably.

2. Technological Advancements

The integration of advanced technologies in poultry farming will continue to evolve, with custom steel structures providing the perfect framework for innovation:

- Automation: The incorporation of automated systems for feeding, watering, and climate control will become standard, enhancing operational efficiency.

- IoT Integration: Smart farming technologies will allow for real-time monitoring of flock health and environmental conditions, further optimizing production.

3. Focus on Sustainability

The emphasis on sustainability will continue to shape the future of poultry farming:

- Eco-Friendly Practices: Custom steel structures will increasingly incorporate eco-friendly materials and energy-efficient systems, aligning with global sustainability goals.

- Circular Economy: The ability to recycle steel and utilize sustainable practices will support the transition to a circular economy in agriculture.

4. Enhanced Focus on Animal Welfare

As consumers become more aware of animal welfare issues, poultry farmers will need to adopt practices that promote the health and well-being of their flocks:

- Better Housing Conditions: Custom steel structures can be designed to provide optimal living conditions for poultry, contributing to better animal welfare outcomes.

- Compliance with Standards: Compliance with welfare standards will be easier with the customizable designs of steel structures, allowing farmers to meet regulatory requirements and consumer expectations.

Conclusion

Custom steel structure buildings offer numerous advantages for poultry farming, including flexibility, durability, biosecurity, and cost-effectiveness. Lida Group’s commitment to providing tailored solutions positions it as a leader in this evolving industry.

As the demand for poultry products continues to grow, the benefits of custom steel structures—enhanced operational efficiency, scalability, and sustainability—make them an ideal choice for modern poultry operations. By investing in these innovative buildings, poultry farmers can improve their productivity while ensuring the welfare of their flocks and contributing to a more sustainable future.

With Lida Group at the forefront of this transformation, the future of poultry farming looks promising. Embracing custom steel structure buildings is not just a trend; it is a strategic move that will shape the next generation of poultry farming.